Peripheral delivery braided sheath technology might not be the headline in a cath lab, but it often decides whether a device tracks cleanly, torques predictably, and maintains a round, open lumen when the case gets difficult. In high-stakes procedures, this quiet part shapes safety and speed. Why do some systems feel crisp while others drift or kink? How can small choices in braid, liner, and jacket change outcomes at the table? Today, we open the sheath and show what really matters. Stay with us to see the simple rules that boost accuracy – and the hidden traps that waste time.

Why Precision Is The First Safety Feature

When clinicians talk about ” feel,” https://www.demaxoem.com/product/braid-coil-reinforcement-tubethey’re describing how accurately a system follows intent through tortuous paths, across tight curves, and past vulnerable structures. A peripheral delivery braided sheath helps turn subtle proximal inputs into reliable distal motion. It resists kinking at sharp bends, protects lumen geometry under push, and preserves flow even when devices share the same pathway. Those small wins add up – fewer corrections, less contrast, shorter fluoroscopy time, and lower operator fatigue.

Demax designs specifically around recurring pain points across vascular, endoscopic, and urologic access:

• Kink Resistance & Lumen Integrity: Braid and coil reinforcement keep the lumen circular under load, reducing flow stalls and device hang-ups.

• Clean Torque Transmission: Tuned pick counts and wire geometry support true 1:1 rotation, which improves steering in complex anatomy.

• Pushability With Feedback: Layered stiffness keeps the proximal segment supportive while the distal segment remains supple, so the system advances rather than ” plows.”

• Lot-To-Lot Consistency: Intelligent production lines watch tension, thermal profiles, and braid density to minimize drift and shorten validation loops.

- The Hidden Costs Of ” Almost Good Enough”

A sheath that nearly performs still wastes time and money. • Repositioning to recover lost trackability lengthens procedures. • Poor torque response increases the risk of vessel trauma during repeated corrections. • Variability forces wider acceptance criteria, driving rework and returns. Demax’s approach is to tighten process windows – so your bench data shows up in the procedure room exactly as expected.

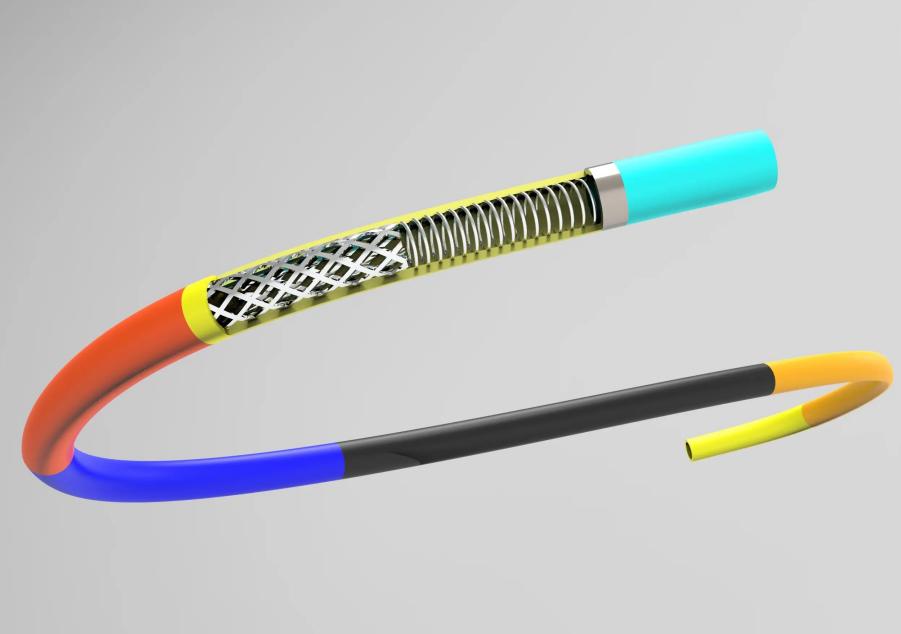

Inside The Engineering

The Demax Braid & Coil Reinforcement Tube is the backbone of our peripheral delivery braided sheath builds. It balances strength, flexibility, and low friction to support angiography, guiding catheters, microcatheters, guide sheaths, and distal access catheters. It also serves endoscopy, urology, surgical access, and diagnostic imaging where controlled bending and stable flow are non-negotiable.

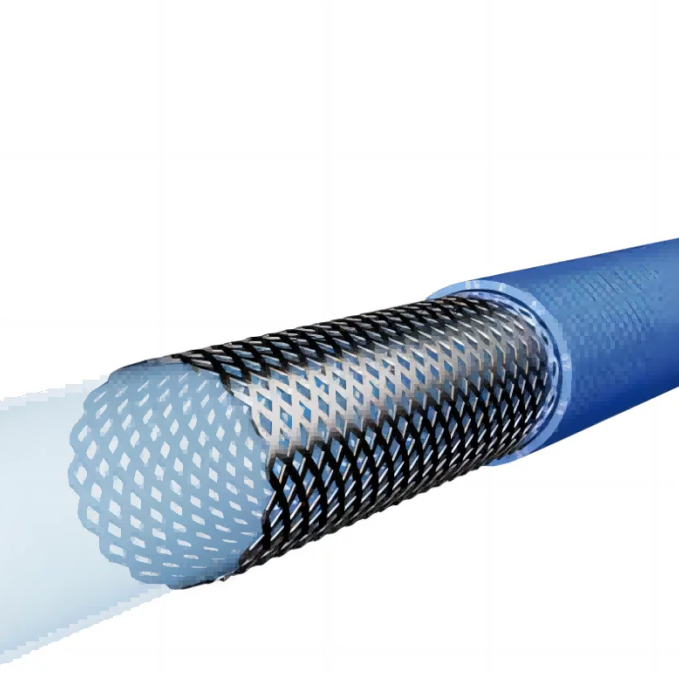

- Layered Construction That Does The Work

• Outer Layer: TPU, Pebax, or PA tuned for abrasion resistance and bend behavior.

• Reinforcement Layer: SUS304, nickel-titanium (Nitinol), or stainless steel wires in round or flat profiles; braid and/or coil architectures to match torque and kink targets.

• Inner Layer: PTFE, TPU, Pebax, or PA; PTFE liners deliver low friction for device exchange and precise fluid delivery.

This architecture underpins high torque transmission, robust operability, strong pushing force, and anti-explosion / anti-bending performance – traits that keep a peripheral delivery braided sheath stable when anatomy pushes back.

- A Mechanical Envelope You Can Shape

Demax supports inner diameters from 5 – 15 mm, with inner diameter tolerance around ±0.125 mm, wall thickness roughly 0.7 – 3.0 mm, and outer diameter tolerance about ±1 mm. We tune weave density (PPI), coil spacing, tube diameter, and stiffness gradients to your indication. Braid spindle options – 8, 16, 32, 48, 72 – and patterns (1×1, 1×2, 2×2) give us a broad design surface to balance torque, flexibility, and kink resistance for the navigation tasks you care about.

✅ Where The Sheath Earns Its Keep

• Vascular Interventions: During angiography, angioplasty, or stent delivery, predictable torque and a round lumen protect flow and improve device passage.

• Endoscopy: In gastroscopy, colonoscopy, and bronchoscopy, reliable bending and steady suction/irrigation improve visibility and efficiency.

• Urology: Cystoscopy, ureteroscopy, and nephrostomy benefit from smooth delivery of saline, contrast, and therapeutics through consistent lumens.

• Surgery: Laparoscopic, arthroscopic, and neurosurgical access lines must resist crush and collapse – braid/coil reinforcement keeps channels open.

• Imaging: In CT, MRI, and ultrasound workflows, a stable, low-friction path helps time contrast precisely for clearer pictures.

Demax As A Build Partner

Strong bench data is only as good as the process that reproduces it. Demax integrates materials science, precision tooling, and intelligent manufacturing production lines so performance you validate is the performance you receive at scale. That continuity is especially important for a peripheral delivery braided sheath, where minor drift in braid tension or liner finish can change torque, trackability, and burst margins.

✅ How Demax Reduces Risk End-To-End:

• ODM Co-Development: We collaborate on catheter shafts, guide wires, and reinforced tubing to shorten iteration cycles and clarify trade-offs early.

• Precision Molds & Tooling: In-house injection molds and liners deliver repeatable IDs/ODs and smooth inner surfaces that preserve low friction over long lengths.

• Process Intelligence: Closed-loop controls track braid tension, PPI, and thermal history; better Cpk means fewer surprises and cleaner validations.

• Scalable Cells: Modular lines expand capacity while preserving set-ups, so scale-up doesn’t require re-learning your acceptable windows.

We also help teams move faster through verification and submission with documented test methods – torque, kink radius, burst pressure, trackability, and fatigue – matched to your use conditions. The goal is simple: a peripheral delivery braided sheath that behaves on day one exactly like it will on day one thousand.

✅ Practical Tips For Your Next Design Review

• Align On Use Paths: Map the tortuosity, bend radii, and expected forces; select braid pattern and wire profile accordingly.

• Guard The Liner: Low friction is a system property – specify surface finish, lubricious liners, and bonding steps that protect it through sterilization.

• Design For Assembly: Confirm that torque and stiffness survive jacket bonding, hub assembly, and thermal processes.

• Specify What Matters: Call out PPI, tension windows, and thermal profiles in drawings to freeze what your performance depends on.

Call To Action

If your roadmap includes tighter navigation, cleaner torque, and fewer mid-case surprises, partner with Demax. We’ll co-define the target ID/OD, stiffness profile, braid pattern, and liner strategy, then build samples on production-capable equipment so scale is built in from day one. Contact Demax for engineering support, tailored samples, or a rapid DFM review – and turn your peripheral delivery braided sheath into a measurable advantage in precision and safety.