GI Stent Delivery system success starts long before the stent meets the stricture. In the procedure room, the wire defines the path, the pace, and the predictability of every move. If torque does not transmit cleanly, if visibility fades, or if the tip irritates tissue, the whole case slows. From Demax’s vantage point – as a manufacturer of world-class medical catheters, medical guide wires, ODM solutions, precision tubing, precision injection molds, and intelligent manufacturing lines – the takeaway is straightforward: the surest way to elevate a GI Stent Delivery system is to pair it with a purpose-built disposable guidewire that makes difficult anatomy feel routine.

The Real Bottleneck In GI Stent Delivery System Workflows

❓ Where Procedures Slip – and Why That Costs You?

Stent platforms are reliable; it is the ” rail” that often wobbles. Tight, angulated segments, scarred strictures, and limited fluoroscopic windows turn an average wire into a liability. When kinks form or the tip position becomes uncertain, momentum stalls. Every extra exchange means more radiation, more stress, and more opportunity for error. Teams do not plan for these micro-delays, yet they add up across a full day list.

Routine frustrations share the same roots: insufficient torsional control, drag that masks tactile feedback, and tip designs that either snag or slide unpredictably. A better partner wire restores confidence. It preserves the line you have earned, steadies device delivery, and keeps the GI Stent Delivery system moving forward without drama.

• Access Through Difficult Anatomy: Scarred or sharply angled tracts demand crisp torque transmission with strong kink resistance.

• Clear, Consistent Visualization: Under X-ray, the wire should ” read” at a glance so operators know where the tip is and how fast it is moving.

• Atraumatic Progress: Gentle advancement protects fragile mucosa and lowers bleeding or perforation risk.

• A Stable Rail For Delivery: Once parked, the wire should resist buckling while the GI Stent Delivery system tracks over it.

• Clean, Low-Risk Exchanges: Single-use design reduces cross-contamination and maintains speed in complex cases.

Those are not comfort features; they are outcome features. They influence procedure time, radiation exposure, and patient safety.

How Demax‘s Disposable Guidewire Becomes The Better Partner

- Engineering That Matters At The Tip, Core, And Surface

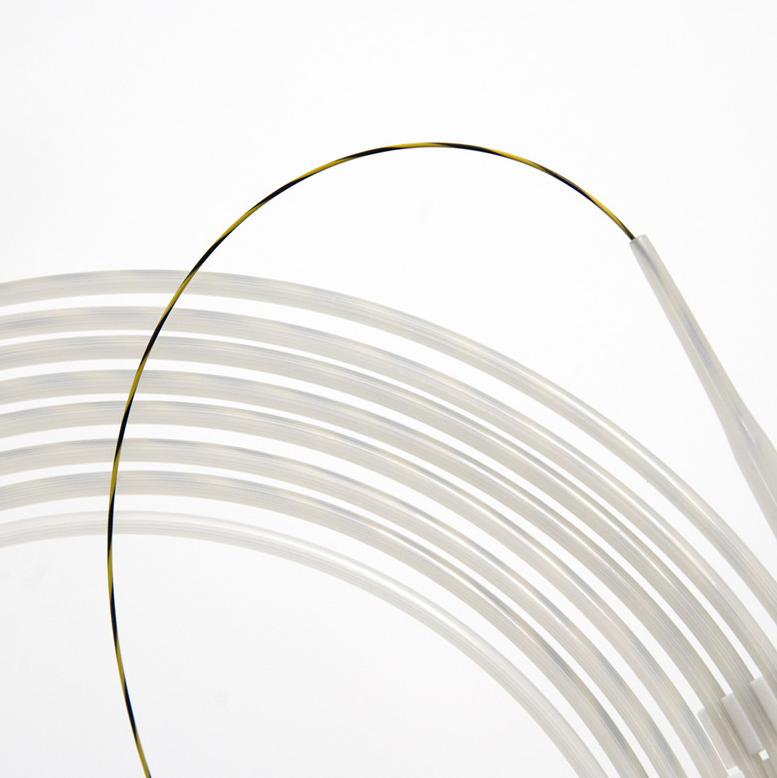

Demax’s Disposable Guidewire for Digestive Tract and Airway is built to be the calm center of a high-stakes procedure. It combines materials science with thoughtful details that show up on fluoroscopy and in your hands.

• Elastic Nitinol Core With Anti-Kink Behavior: The core stores and releases energy smoothly, preserving torque even in tight bends. You steer with intent, not with guesswork.

• Ultra-Smooth PTFE (Teflon) Coating: Low friction means lighter pushes and truer tracking. A two-tone spiral pattern enhances motion awareness under imaging so subtle shifts are easy to see.

• Hydrophilic, X-Ray-Friendly Soft Tip: The tip wets quickly, glides with minimal force, and is easy to position across a stricture when every millimeter matters.

• Rounded, Tissue-Kind Profile: The contour reduces irritation in GI and airway passages, supporting atraumatic access.

• Reinforced Soft-Tip Connection: Robust joining technology keeps the interface secure – no wobble, no surprise disconnections during exchanges.

• Choice Of Builds And Geometries: Pre-shaped, coated, and zebra options let you tailor handling for biliary, long GI, or airway routes.

- The Real-World Impact You Feel

Pair this wire with your GI Stent Delivery system and small problems stop snowballing. Tracking is smoother, repositioning is faster, and the tip ” tells the truth” under X-ray. In short cases, you notice less friction and fewer instrument swaps. In long, tortuous runs, you keep the line you fought for and avoid kinks that force a reset. That is not just convenience; it is better focus, steadier teamwork, and more predictable throughput.

Behind the wire is Demax’s integrated manufacturing ecosystem: precision tubing, injection tooling, and intelligent production lines that lock in repeatability. Consistent inputs create consistent behavior – case after case, operator to operator, site to site.

Indications, Specs, And Next Steps

✅ Where It Works Best

The wire is optimized to support a GI Stent Delivery system, yet its utility spans a wide range of digestive and airway procedures that often share the same pain points:

• Endoscopic Retrograde Cholangiopancreatography (ERCP): Secure navigation of biliary or pancreatic ducts with a stable platform for stent placement.

• Endoscopic Ultrasound (EUS): Smooth probe advancement and reliable device exchange for diagnostic and therapeutic interventions.

• Bronchoscopy: Controlled access and stent deployment in airway strictures, plus support for foreign body retrieval and biopsy.

• EMR/ESD: Guided, deliberate device passage during lesion resection where precise tip control is crucial.

• Endoscopic Stenting (GI and Airway): A dependable rail for crossing tight strictures and delivering stents without buckling.

✅ Key Specifications At A Glance

• Diameter: 0.035″ for broad compatibility with endoscopic accessories.

• Effective Lengths: 180 cm, 260 cm, and 450 cm to match short duodenal, long colonic, or extended airway paths.

• Configurations: J-tip and Straight; plus pre-shaped, coated, and zebra options to align with your case mix.

These choices help you fit the rail to the route, ensuring your GI Stent Delivery system advances as intended – smoothly, steadily, and with fewer surprises.

Selecting A Partner For Today – And Standardizing For Tomorrow

Many units accept minor inefficiencies as routine: a small kink here, a vague tip there, an extra exchange to ” be safe.” The cost is hidden in schedule drift, team fatigue, and cumulative radiation. Upgrading the guidewire is a practical lever with outsized effects: clearer imaging cues, better torque feel, fewer resets, and a calmer room.

Demax does more than ship wires. As a full-stack manufacturer – medical catheters, guide wires, ODM development, precision components, and intelligent production – we can help you validate the right configuration for your typical anatomy and device set, then standardize it across teams for consistent results.

Call To Action: Ready to give your GI Stent Delivery system the partner it deserves? Contact Demax to trial the Disposable Guidewire for Digestive Tract and Airway in your next stent cases. Our engineering team will help align specifications with your workflow, and our ODM capability enables rapid, quality-assured customization for hospitals, endoscopy centers, and distribution partners. When the guidewire becomes a true ally, the stent goes where it should – predictably, safely, and on time.