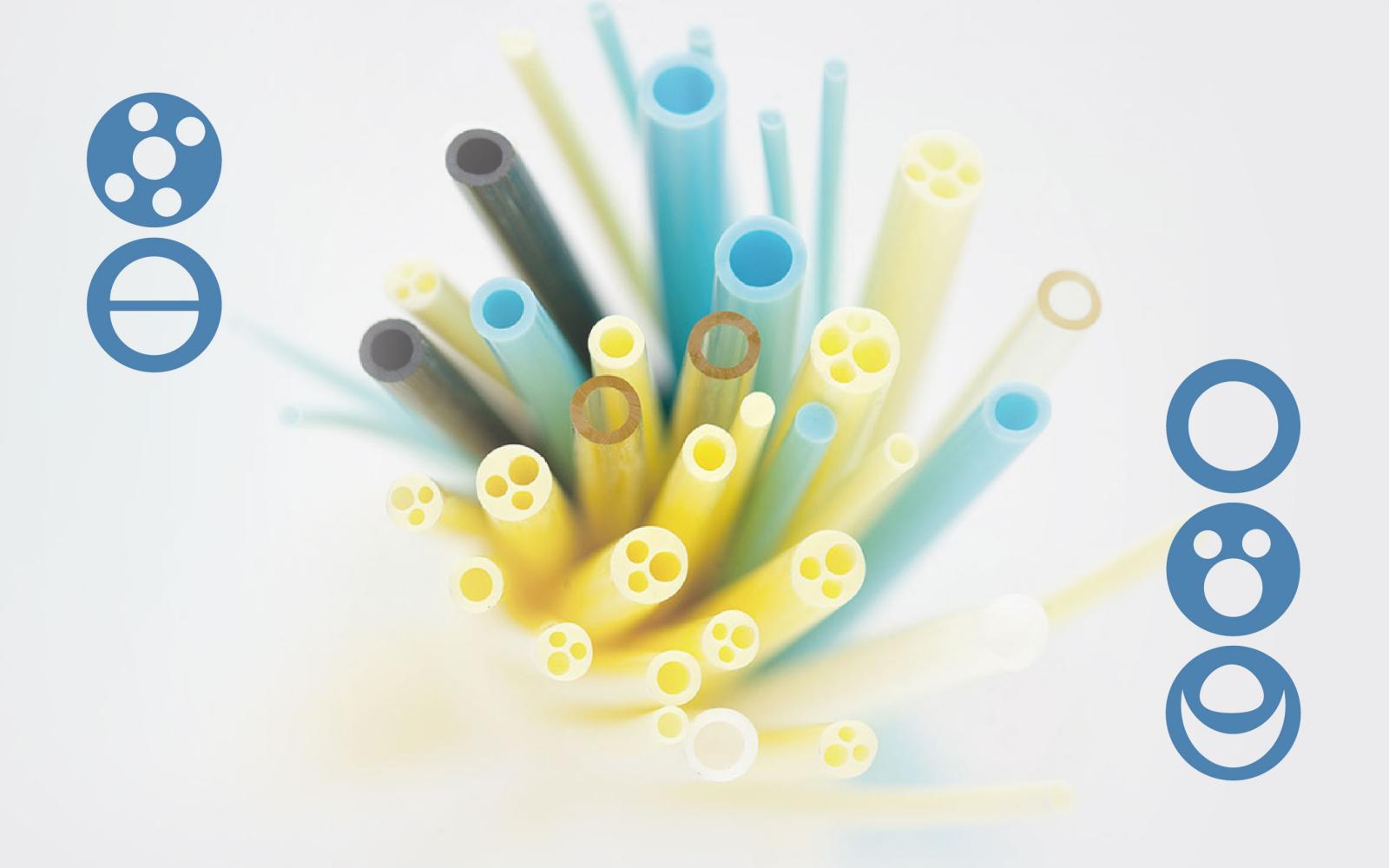

In healthcare manufacturing, the choice of a Medical extrusion tubing supplier shapes device performance, regulatory success, and the real cost of every shipped unit. For Demax, that decision is never a coin toss between “cheap” and “safe.” We build for reliability first, then remove waste everywhere it hides – from resin selection and tooling to documentation and logistics. This article explains how to strike a durable balance between price and assurance, and how Demax‘s ODM approach helps you get there without surprises.

Why Cost And Quality Both Matter

Cutting visible costs can inflate invisible ones. When tubing wall thickness drifts or durometer varies, downstream yields slide, cycle times stretch, and line operators fight avoidable rework. Adhesive bonds lose strength; kink resistance dips; burst pressure misses the spec. Each deviation triggers extra inspections, line stoppages, and nonconformance reports. The dollars show up later as missed takt, scrapped assemblies, and delayed shipments.

Documentation gaps add another layer of risk. Late PPAPs, partial CoCs, or weak change control do not merely frustrate auditors – they slow launches, complicate submissions, and erode customer confidence. Logistics can amplify the pain: long lead times, rigid MOQs, and resin volatility all ripple through planning and inventory.

A dependable Medical extrusion tubing supplier prevents those compounding losses. At Demax, we treat quality as the shortest path to lower total cost. We start with the clinical use case and design for manufacturability from day one. Materials are chosen for sterilization method, biocompatibility, and shelf life, not just initial price. Tolerance stacks are modeled for OD/ID, lumen geometry, radiopacity, and surface behavior so the tube you qualify is the tube you keep receiving at scale. The outcome is simple: less scrap, stable takt, and a launch schedule that holds.

- The Real Price Of “Cheap” Tubing

A few cents saved per meter can become dollars lost per device. Subtle issues – gel specks, particulates, inconsistent annealing – can trigger property drift after sterilization or during aging. Demax limits that risk through traceable materials, controlled extrusion windows, and data-backed verification. You should never pay for the same tubing twice.

How Demax Delivers Value Without Cutting Corners

Demax provides world-class medical catheters, medical guide wires, precision tubing, precision injection molds, intelligent manufacturing lines, and full ODM services. Our approach blends advanced engineering with practical factory discipline so you don’t have to choose between performance and predictability.

- Design To Verification: Building In Reliability

We co-create with your team, translating clinical intent into measurable specifications. Early DFM and design reviews reduce late changes that destroy timelines and budgets. Rapid prototype sample production proves feasibility quickly and clarifies true cost drivers – geometry limits, material interactions, secondary processes – before you lock the design. Under our ISO 13485 quality system, we verify components, assemblies, and finished products for safety and performance, ensuring the documentation package supports submissions and audits.

Demax’s ODM model covers the entire journey: concept, design engineering, risk analysis, verification, validation, and transition to manufacturing. The goal is consistent: eliminate unknowns, show the data, and move at a steady, confident pace.

- Manufacturing Discipline, Data, And Scale

In production, control is everything. Demax relies on laser micrometry, in-line monitoring, and lot-level traceability to maintain OD/ID, concentricity, and mechanical properties over long runs. Intelligent lines and SPC keep processes inside a tight window, while structured change control protects continuity as volumes grow or materials shift. This is how a Medical extrusion tubing supplier turns unit cost into total value: fewer interruptions, fewer returns, and faster responses when regulators ask for evidence.

Beyond tubing, our capabilities span diagnostic tools, patient monitoring devices, healthcare equipment, implantable solutions, and wearables. That ecosystem view matters. It lets us tune tubing behavior to the real system – pull strength for assembly, torque for navigation, surface finish for drug delivery – so you aren’t optimizing one part at the expense of the device.

A Practical Buyer‘s Checklist And Your Next Step

Price matters. So do risk, long-term stability, and evidence. Use the checklist below to compare partners and ask Demax to show the data behind every claim. A trustworthy Medical extrusion tubing supplier will welcome the scrutiny.

✅ Quick Evaluation Checklist

• Application Fit – Does the supplier convert clinical use into testable specs (burst, kink radius, friction, radiopacity) with acceptance criteria that match your risk profile?

• Material Strategy – Are resin options aligned with sterilization and biocompatibility needs, with second-source planning to reduce supply risk?

• Process Capability – Can they demonstrate stable Cpk for OD/ID and wall thickness at production speed, not just pilot runs?

• Verification & Records – Are CoA/CoC, PPAP, and change control complete, timely, and audit-ready for submissions and customer reviews?

• Lead Time & Capacity – Do they maintain flexible MOQs and scalable capacity so your ramp plan survives market demand swings?

• Total Cost Proof – Can they quantify how quality reduces scrap, deviations, and delays across your entire build, not just the tubing line?

Demax’s offering goes further than a meter price. You gain integrated catheter and guide wire development for system-level fit, precision injection molds that lift repeatability and throughput, and automated cells that stabilize quality shift after shift. Our end-to-end ODM services streamline documentation and verification so regulators get what they need the first time.

✅ What You Gain Beyond Tubing

● System-level design alignment that reduces surprises in assembly and clinical simulation

● Faster feasibility cycles with clear readouts on risks, costs, and trade-offs

● Manufacturing discipline that scales without constant firefighting

The bottom line: a Medical extrusion tubing supplier should reduce risk, compress timelines, and simplify compliance while protecting your budget. That is the Demax promise – design partnership, rigorous verification, and factory execution that make performance repeatable and costs predictable.

Call-To-Action

Ready to balance cost with confidence? Connect with Demax for a focused review of your tubing specs, material options, and scale-up plan. We’ll deliver a concise feasibility outline, timeline, and path to production – so you launch faster, with fewer surprises, and with a partner invested in your success.