Medical guidewire Price is the first question many buyers ask. The better question is what pushes it up – or brings it down. Is it the metal inside the core? The coating on the surface? The way a tip is shaped and finished? Or forces outside the factory, like regulations and supply chains? Each guess sounds right, yet none tells the full story. In the next sections, we unpack the real drivers. One factor surprises most teams – and it changes how you plan your budget. Ready to find it?

1) Materials, Design, And Process Discipline

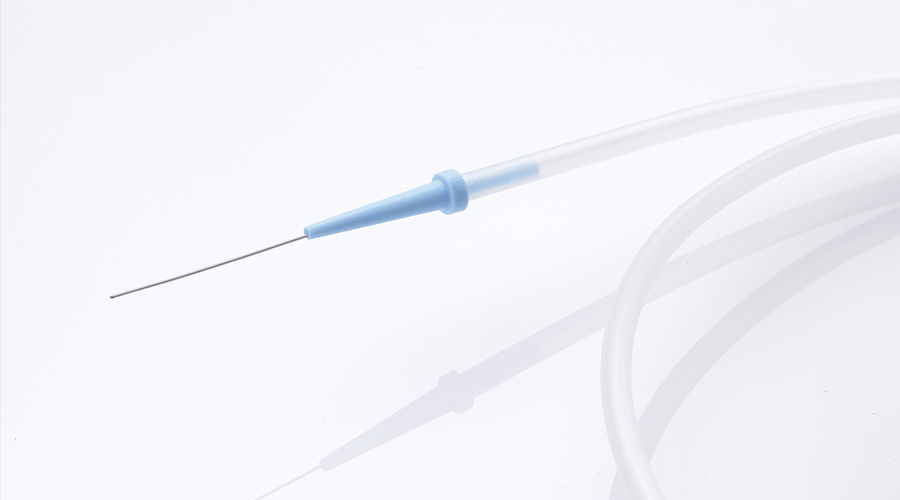

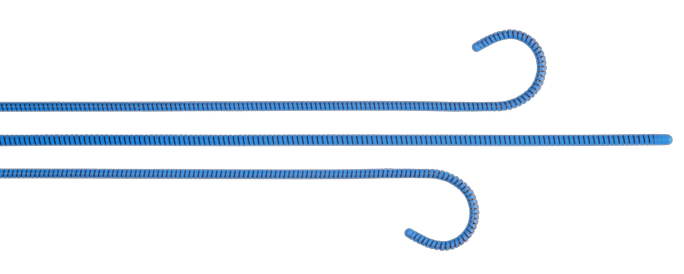

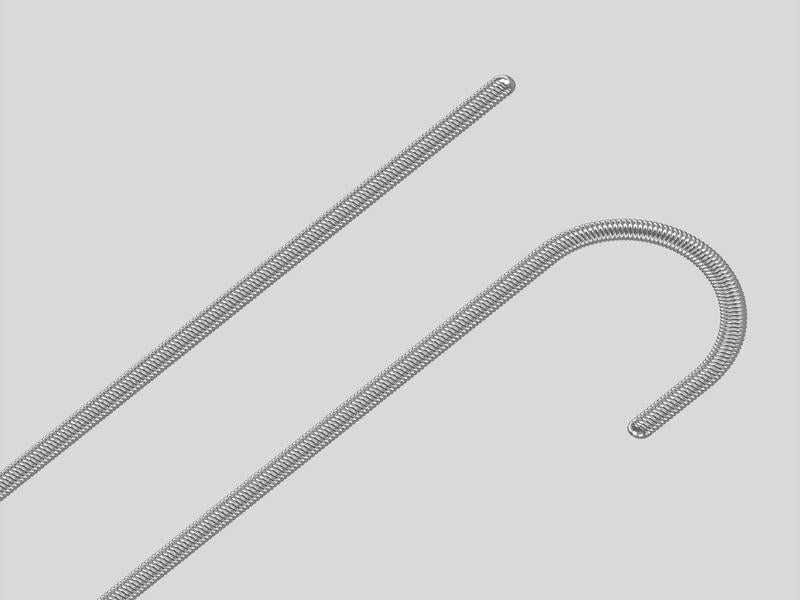

The materials inside a guidewire are not interchangeable commodities. They define how a wire steers, how it feels in the hand, and how reliably it completes a case. Nitinol for flexibility and shape memory, stainless steel for push and torque, PTFE liners for low friction, and hydrophilic or hybrid coatings for glide – each choice changes Medical guidewire Price and performance. When anatomy is tortuous or lesions are calcified, the material stack and coil design become more sophisticated, adding cost but also delivering safety and control.

At Demax we manage the stack end-to-end. Precision tubing and precision injection molds hold tight wall tolerances and clean transitions from core to coil to jacket. Our intelligent manufacturing lines use in-line measurement, closed-loop feedback, and digital traceability to keep every wire within spec. Scrap and rework fall. Yields rise. Price becomes more predictable because variation is contained at the source.

Why Process Details Matter?

A coating that feels “slick” in a demo must also last in real procedures. Uniform application, cleanliness, and validated curing preserve lubricity and reduce particulate risk. Tip shaping demands repeatable heat profiles; even small deviations can alter trackability. These are not cosmetic steps. They protect patients, and they stabilize Medical guidewire Price by avoiding waste and post-market headaches.

✅ Common Pain Points We Address

• Torque versus budget: Low-cost cores can blunt torque response. We tune core-to-coil interfaces so steering remains precise without letting cost run away.

• Coating life: Early coating wear increases clinical risk and total cost of ownership. Our validated processes extend durability under real-world loads.

• Batch consistency: Hospitals value predictability. SPC analytics and automated lines reduce drift so performance – and pricing – stay steady.

2) Compliance, Scale, And Supply Assurance

The second layer of Medical guidewire Price sits behind the spec sheet: quality systems, regulatory rigor, and supply resilience. In modern healthcare, these are not optional. They are the foundation of trust.

Quality and regulatory. ISO-compliant QMS, risk files, biocompatibility evidence, sterilization validation, and full traceability all add time and expense. They also prevent field failures and costly recalls. Demax plans for these requirements from project kick-off rather than bolting them on later, so compliance effort is efficient and repeatable.

Supply chain stability. Markets for specialty alloys, high-performance polymers, and coating chemistries can be volatile. A single shortage can lead to expedited freight, last-minute substitutions, or missed cases. We qualify multiple sources, maintain strategic safety stocks, and integrate procurement signals with production scheduling. That discipline lowers the hidden taxes that creep into Medical guidewire Price when supply chains wobble.

Scale and automation. Intelligent manufacturing – automated winding, laser metrology, machine vision inspection, and digital batch records – reduces labor per unit and compresses lead times. As volumes climb, tooling and validation costs amortize across more devices. This is especially powerful in ODM programs, where shared platforms shorten time to market and smooth per-unit cost without compromising performance.

✅ What Buyers Gain In Practice

• Fewer emergency premiums: Better planning and stable sourcing reduce rush fees and weekend changeovers.

• Lower lifetime cost: Consistent wires cut procedure time and device waste, improving total economics.

• Predictable quotations: Validated processes help keep Medical guidewire Price inside planned ranges – even when markets shift.

3) Value Beyond The Wire: ODM, Service, And Total Cost

The final driver of Medical guidewire Price is everything that happens outside the sterile pouch: engineering collaboration, manufacturability choices, training, and post-market vigilance. A wire with a low sticker price but high failure rate is not inexpensive. True value is the product plus the system that keeps it reliable.

ODM collaboration. Demax offers ODM products built on proven catheter and guidewire platforms. Partners do not start from zero; they iterate on architectures already engineered for performance and manufacturability. Verification is faster. Tooling risk is lower. Documentation is cleaner. The launch improves, and the cost curve becomes friendlier over time.

Design for manufacturability. Early DFM/DFA reviews align clinical targets with production realities. Small choices – coil pitch, jacket transitions, or coating windows – can remove entire sources of variability. The result is fewer deviations, fewer change orders, and a smoother Medical guidewire Price profile across the lifecycle.

Lifecycle service and learning. Training for clinical teams, structured complaint analysis, and continuous improvement loops keep the product competitive without destabilizing cost. When field data highlights a stress case, we adjust quickly and document thoroughly, protecting both outcomes and budgets.

✅ How To Optimize Your Medical Guidewire Price With Demax?

• Share real use scenarios: Vessel anatomy, device compatibility, and torque needs guide the right material and design choices.

• Engage early on ODM: Co-engineering trims months, reduces redesigns, and avoids hidden costs.

• Plan volume ramps: Forecasted demand supports tooling and automation that unlock better pricing.

• Think beyond unit price: Consistency, shorter procedures, and assured supply often outweigh a small discount.

- Product And Capability Snapshot

Demax provides a broad set of capabilities to support these outcomes: world-class medical catheters and medical guide wires, custom ODM development, precision tubing, precision injection molds, and intelligent manufacturing production lines. Because these pieces sit under one roof, communication loops are short and accountability is clear. That integration is a quiet but meaningful reason our customers see stable performance and a stable Medical guidewire Price.

Call To Action

If your goal is to stabilize Medical guidewire Price while improving clinical performance, let’s talk. Connect with Demax for a brief technical consultation. We will review your current usage, map the real cost drivers, and propose a materials-plus-process plan anchored in intelligent manufacturing. Whether you need standard guide wires, advanced catheters, precision components, or a full ODM path, Demax helps teams deliver safer outcomes – at a price they can plan for.