Guiding catheter OEM programs give clinicians more control in difficult vascular cases and help teams deliver consistent, repeatable results without adding complexity.

Why Customization Matters In The Cath Lab

Hospitals and device makers face real pressure: tighter timelines, higher costs, and patients with increasingly complex anatomy. Standard catheters can work for routine access, yet they often struggle in tortuous vessels or when multiple devices must pass quickly and safely. A tailored Guiding catheter OEM approach closes this gap by matching engineering to the exact clinical task.

At Demax, every project begins with clinical intent. We map the workflow, imaging requirements, and the accessory set used at the table. That focus reduces device change-outs, shortens procedure time, and supports better outcomes. It also stabilizes supply. When engineering and manufacturing align early, variability drops, validation moves faster, and scale-up becomes predictable.

✅ Typical Use Cases

• Coronary angiography and angioplasty: stable access and reliable device exchange

• Peripheral interventions: long paths demand push, track, and clear visualization

• Neurovascular procedures: delicate navigation with soft, atraumatic tips

• Embolization and ablation: precise delivery of coils or agents to target sites

• Thrombectomy and vascular access: coaxial control for clot removal and placement

Call-to-Action: Have a tricky access pathway or a new indication in mind? Talk to Demax for a fast, risk-aware Guiding catheter OEM plan tailored to your procedure mix.

Engineering That Delivers At The Table

Customization is more than a drawing or a sample. It is material science, structural design, and human factors working together so the catheter feels predictable in the physician’s hands.

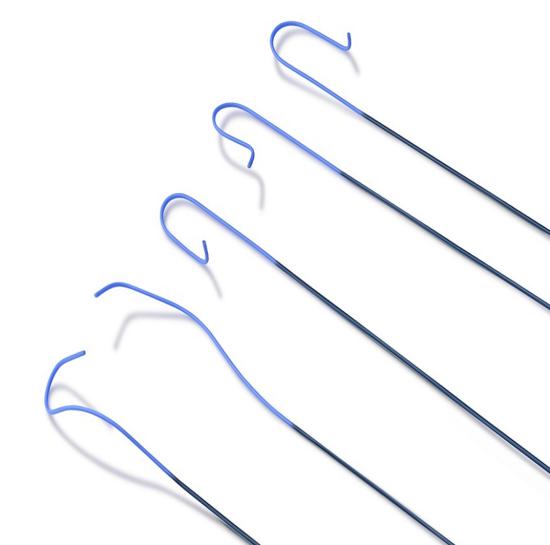

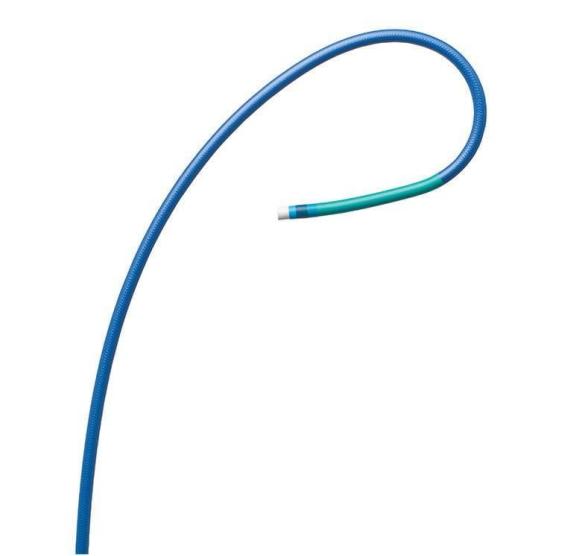

Demax guiding catheters use biocompatible polyurethane or nylon for flexibility, durability, and tissue compatibility. The shaft combines braided or coiled reinforcement to provide support and torsional response without losing the bend needed for complex anatomy. Soft, atraumatic tips help protect vessel walls during entry and repositioning. Radiopaque markers increase visibility under fluoroscopy, making navigation and final placement precise and repeatable.

✅ Feature Highlights For Guiding Catheter OEM

• Soft Tips: Smooth access with clear visualization while minimizing trauma and improving patient comfort.

• Large Chamber: A generous internal diameter – 1.80 mm for 6F – improves compatibility with wires, balloons, stents, and other consumables, reducing friction and exchanges.

• Solid Wall Structure: Reinforced walls produce robust support and dependable torsion control in challenging lesions without sacrificing trackability.

• Good Coaxiality: Maintains alignment to difficult targets for accurate device delivery and effective therapy.

• Radiopaque Markers: Confident positioning under imaging with fewer reposition attempts.

These elements are paired with consistent lubricity and kink resistance to deliver a familiar, controlled feel. The result is fewer mid-case surprises, smoother workflows, and a team that can focus on treatment rather than fighting the access platform.

❓ What It Means In Practice?

For clinicians, a well-tuned platform means predictable torque, stable seating, and steady visualization – even when anatomy is unforgiving. For OEM partners, it means fewer iterations, cleaner verification data, and a clearer path through validation. For patients, it supports shorter procedures and less trauma to the vessel wall. That is the everyday value of a Guiding catheter OEM program built for real cases, not just ideal ones.

Partnering With Demax For Guiding Catheter OEM

Demax is more than a component supplier. We are a manufacturing partner that connects design intent to scalable production. Our scope spans world-class medical catheters, medical guide wires, ODM products, precision tubing, precision injection molds, and intelligent manufacturing production lines.

✅ Integrated Capabilities

• Catheters & Guide Wires: Interventional platforms engineered for access, support, and exchange.

• ODM Solutions: Extend your portfolio without starting from zero.

• Precision Tubing: Tight tolerances to protect lumen integrity and flow.

• Precision Injection Molds: Repeatable, high-yield components for consistent builds.

• Intelligent Manufacturing Lines: Automated steps that scale while preserving quality.

With in-house tooling and automation, we compress lead times and enable design-for-manufacture feedback early – where it matters most. Prototyping becomes faster, validations become smoother, and transfer to volume is more predictable.

✅ Quality, Compliance, And Speed

Regulatory and quality expectations continue to rise. Demax builds quality into the process, not only into final inspection. Material traceability, process controls, and rigorous in-process testing anchor every lot we release. Documentation and change control are structured to support submissions, audits, and lifecycle maintenance for your Guiding catheter OEM programs.

We also design for durability in real use. Structural reinforcement supports torque without collapse. Tip geometry balances flexibility with target engagement. Radiopacity and shaft contrast support efficient imaging. And lumen dimensions – like the 1.80 mm working chamber on 6F – are set to accommodate common accessories and reduce friction during exchanges. These choices are simple on paper but powerful in the lab, where reliability translates into confidence.

Call-to-Action: If your team needs a catheter with a specific torque profile, a larger working lumen, or improved visibility for a new indication, connect with Demax. Share your target anatomy, accessory set, and handling goals – our engineers will outline a clear, phase-gated plan you can execute.

In Summary

Clinical complexity is rising, and supply risk is real. A customized Guiding catheter OEM pathway with Demax aligns materials, reinforcement strategy, tip softness, radiopacity, chamber size, wall design, and coaxiality to the demands of specialized procedures. With an integrated portfolio – catheters, guide wires, ODM services, precision tubing, precision molds, and intelligent manufacturing – Demax shortens the distance from concept to consistent clinical performance.