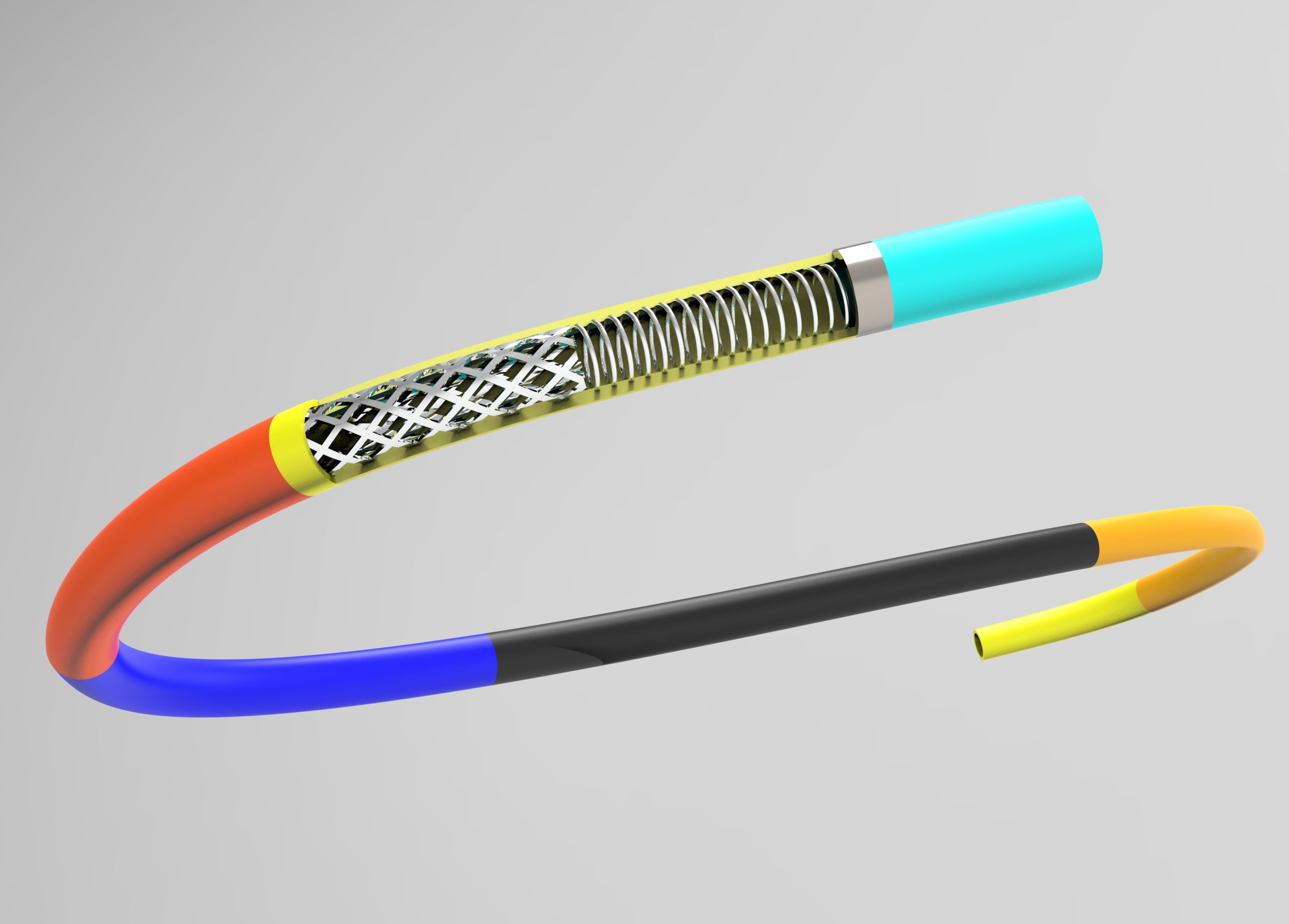

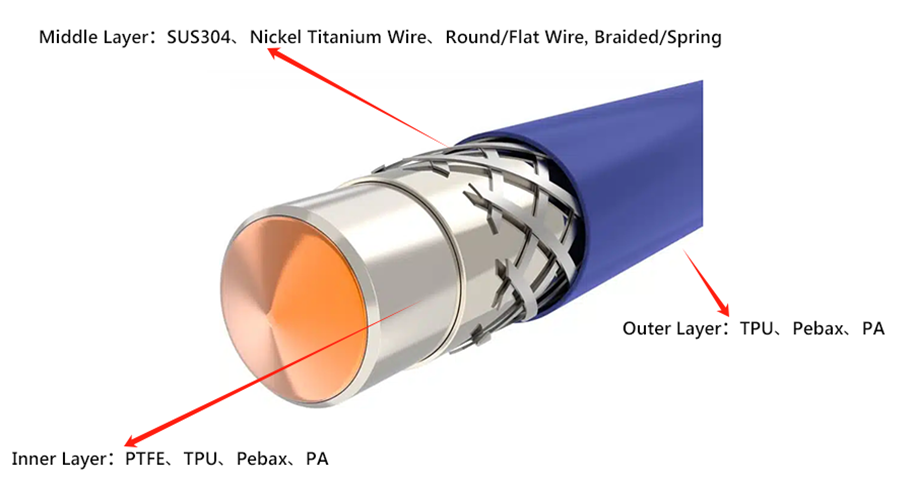

Braid & Coil Reinforcement Tube

The Demax Braid & Coil Reinforcement Tube is an innovative medical device designed to provide enhanced strength and flexibility for a wide range of medical applications. Crafted with precision and utilizing advanced materials, this reinforced tubing offers exceptional performance and reliability, making it an indispensable tool for medical professionals in various clinical settings.

| Inner Diameter(mm) | Inner Diameter Tolerance(mm) | Tube Wall Thickness(mm) | Outer Diameter Tolerance(mm) |

| 0.5-15 | ±0.0125 | 0.07-3 | ±0.01 |

Features

- Outer layer: TPU, Pebax, PA

- Middle layer: SUS304, nickel-titanium wire, stainless steel wire (round wire/flat wire), braided/spring

- Inner layer: PTFE, TPU, PEBAX, PA

- High torque, strong operability,

- Excellent pushing force, anti-explosion and anti-bending capabilities

- Medical-Grade Materials: Ensures biocompatibility and safety for patient use, minimizing the risk of adverse reactions or complications.

Applications

- Angiography Catheter

- Guiding Catheter

- Microcatheter

- Guide sheath

- Distal access catheter

Technical Parameters

- Inner diameter (mm): 5~15

- Inner diameter tolerance (mm): ±0125

- Wall thickness (mm): 07~3

- Outer diameter tolerance (mm):±1

Other Information

- Weaving density (PPI), coil spacing, tube diameter, etc. can all be customized

- Weaving spindle number: 8, 16, 32, 48, 72

- Weaving method: 1×1, 1×2, 2×2

- Vascular Interventions: Used for the delivery of contrast media, saline solution, or therapeutic agents during vascular procedures such as angiography, angioplasty, and stent placement.

Endoscopy: Utilized for the delivery of irrigation fluid, suction, or therapeutic agents during endoscopic procedures such as gastroscopy, colonoscopy, and bronchoscopy.

- Urology Procedures: Used for the delivery of contrast media, saline solution, or therapeutic agents during urological procedures such as cystoscopy, ureteroscopy, and nephrostomy.

- Surgical Procedures: Employed for the delivery of irrigation fluid, suction, or therapeutic agents during surgical procedures such as laparoscopy, arthroscopy, and neurosurgery.

- Diagnostic Imaging: Used for the delivery of contrast media during diagnostic imaging procedures such as computed tomography (CT), magnetic resonance imaging (MRI), and ultrasound.

Related products

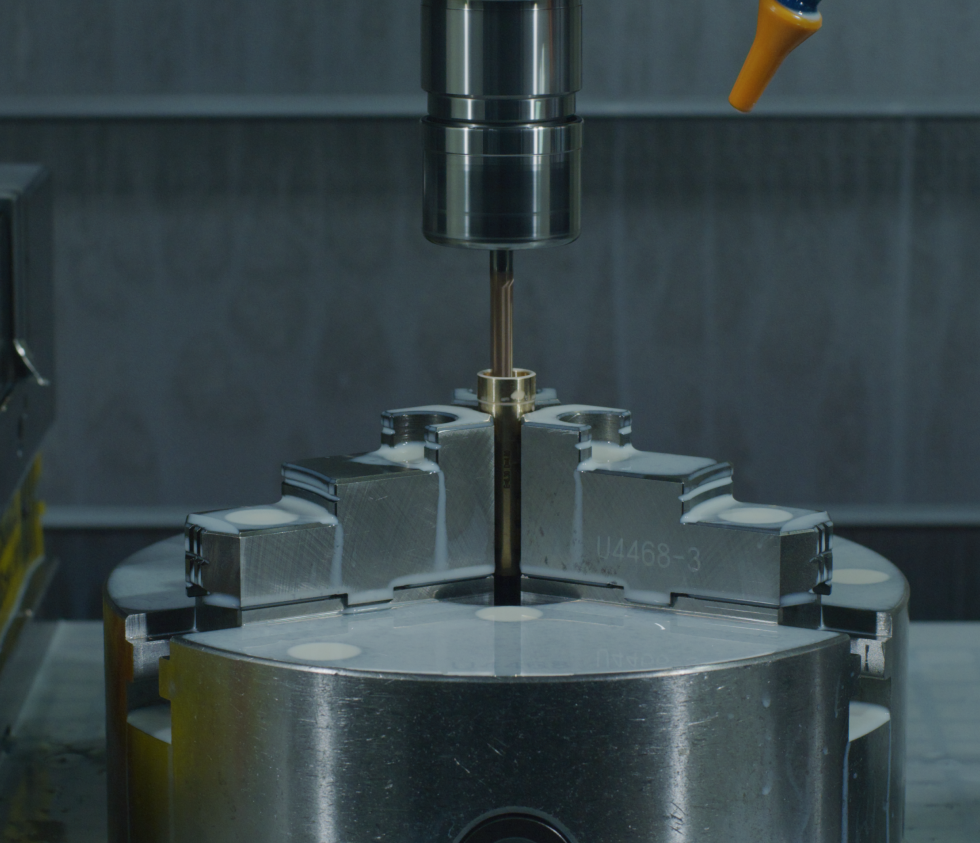

Hook Forming

Demax utilizes high-quality materials such as stainless steel or nitinol for hook forming, chosen for their exceptional mechanical properties, corrosion resistance, and biocompatibility. These materials undergo precise shaping processes to achieve intricate hook configurations tailored to specific medical device applications. With our commitment to quality and precision, Demax ensures that hook-formed components meet the rigorous demands of medical device manufacturing, contributing to the advancement of healthcare worldwide.

Flaring

Precision Medical Tubing Services Flaring involves the precise modification of medical-grade tubing materials to create flares and expansions. The composition of the tubing used in this process varies depending on the specific requirements of the medical device and the application. Typically, medical tubing is made from biocompatible polymers such as polyethylene (PE), polyurethane (PU), polyvinyl chloride (PVC), silicone, or thermoplastic elastomers (TPE). These materials are selected for their flexibility, durability, and compatibility with bodily fluids and tissues.

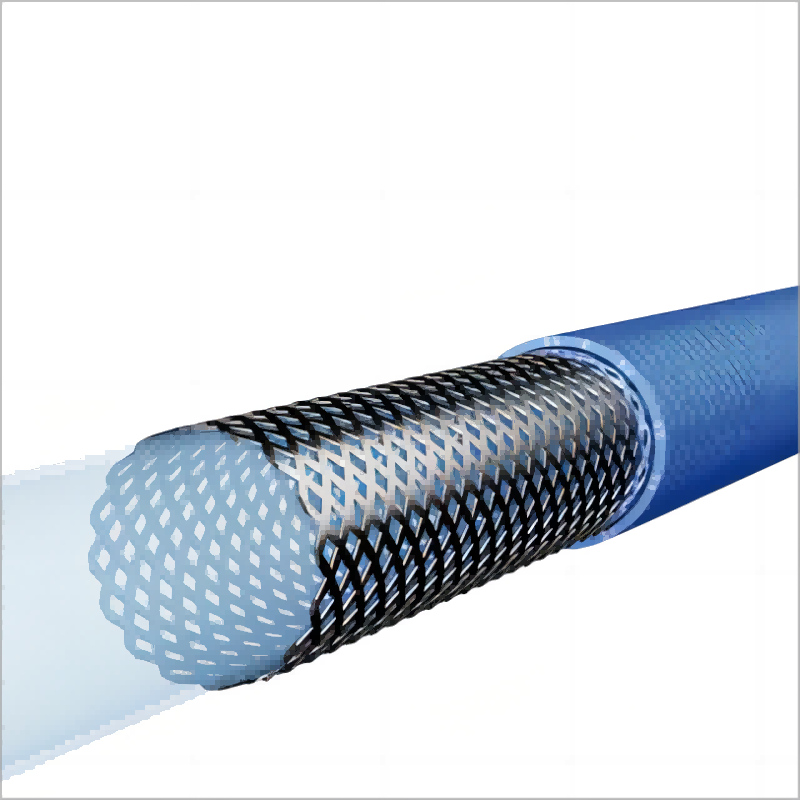

Guiding Catheter

Guiding catheters are typically composed of biocompatible materials such as polyurethane or nylon, chosen for their flexibility, durability, and compatibility with bodily tissues. The catheter shaft is reinforced with braided or coiled wires to provide structural support and torqueability while maintaining flexibility for navigation through tortuous vascular anatomy. Soft, atraumatic tips minimize trauma to blood vessels during insertion and positioning. Radiopaque markers or bands incorporated into the catheter shaft enhance visibility under fluoroscopy or other imaging modalities, allowing for precise navigation and positioning during procedures. Demax’s guiding catheters are engineered with advanced materials and design features to optimize performance and safety, ensuring successful outcomes in a wide range of interventional procedures.

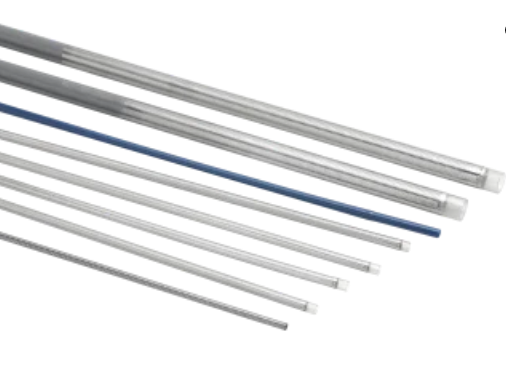

TPU Tube

Demax TPU tubes are meticulously crafted from Thermoplastic Polyurethane (TPU), a premium synthetic polymer renowned for its exceptional elasticity, durability, and resistance to abrasion, chemicals, and environmental factors. This composition ensures the tubes’ longevity and reliability, even in the most demanding conditions. Demax’s commitment to quality extends to every aspect of their manufacturing process, from sourcing the finest materials to employing advanced production techniques. The result is a TPU tube that meets stringent industry standards, providing customers with confidence and peace of mind in their critical applications. Whether in medical procedures, laboratory experiments, or industrial processes, Demax TPU tubes deliver unmatched performance and durability, making them the preferred choice for professionals across various sectors.