Microcatheter

Features:1. PTFE inner layer allows for smooth passage for embolic agents; |

- Outer Diameter: Typically ranges from 0.5 to 3.0 millimeters, depending on the specific application and clinical need.

- Length: Variable, tailored to accommodate different procedural requirements and patient anatomies.

- Material: Constructed from biocompatible materials such as polyurethane, nylon, or PTFE (polytetrafluoroethylene), ensuring compatibility with bodily tissues and minimizing the risk of adverse reactions.

- Tip Configuration: Available in a variety of shapes, including straight, angled, and tapered tips, to facilitate navigation through tortuous vessels and challenging anatomical structures.

- Trackability: Engineered for enhanced maneuverability and trackability, enabling smooth advancement through complex vascular pathways.

- Angiography and Angioplasty: Microcatheters are commonly used in angiography and angioplasty procedures to access and treat narrow or obstructed blood vessels, such as those affected by arterial stenosis or occlusions.

- Embolization: Microcatheters facilitate the delivery of embolic agents to block blood flow to abnormal vessels or tumors, effectively treating conditions such as arteriovenous malformations (AVMs), aneurysms, and uterine fibroids.

- Thrombectomy: Microcatheters enable the mechanical or pharmacological removal of blood clots from blood vessels, restoring normal blood flow and preventing complications such as stroke or pulmonary embolism.

- Drug Delivery: Microcatheters are utilized to deliver therapeutic drugs directly to target sites within the vasculature, enabling localized treatment of conditions such as cancer, peripheral artery disease, and pulmonary hypertension.

- Vascular Access: Microcatheters provide access to the vascular system for diagnostic procedures such as angiography, intravascular ultrasound (IVUS), and fractional flow reserve (FFR) measurements, as well as for the placement of intravascular devices such as stents, balloons, and filters.

Related products

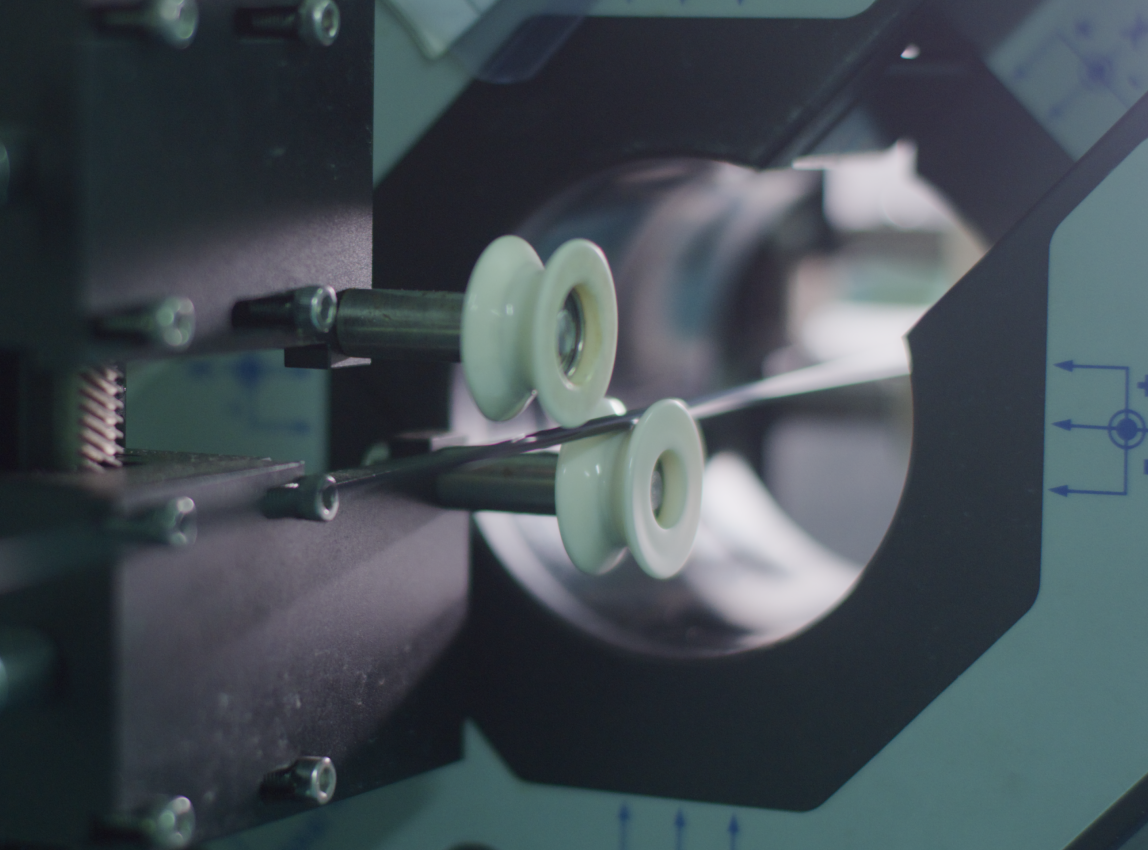

Punching

Precision Medical Tubing Services Punching from Demax involves the precise creation of perforations, holes, or patterns in medical-grade tubing using advanced punching methods and equipment. The tubing material, typically made from medical-grade polymers such as polyethylene (PE), polyurethane (PU), or silicone, is carefully selected for its biocompatibility, flexibility, and durability. During the punching process, specialized punches and dies are used to create holes of specific sizes, shapes, and configurations in the tubing, allowing for precise control over the perforation characteristics. Each punched hole is inspected and verified to ensure that it meets the required tolerances and quality standards. Demax’s expertise in precision punching ensures that punched medical tubing maintains its structural integrity, biocompatibility, and performance, meeting the demanding requirements of medical device manufacturers and healthcare professionals.

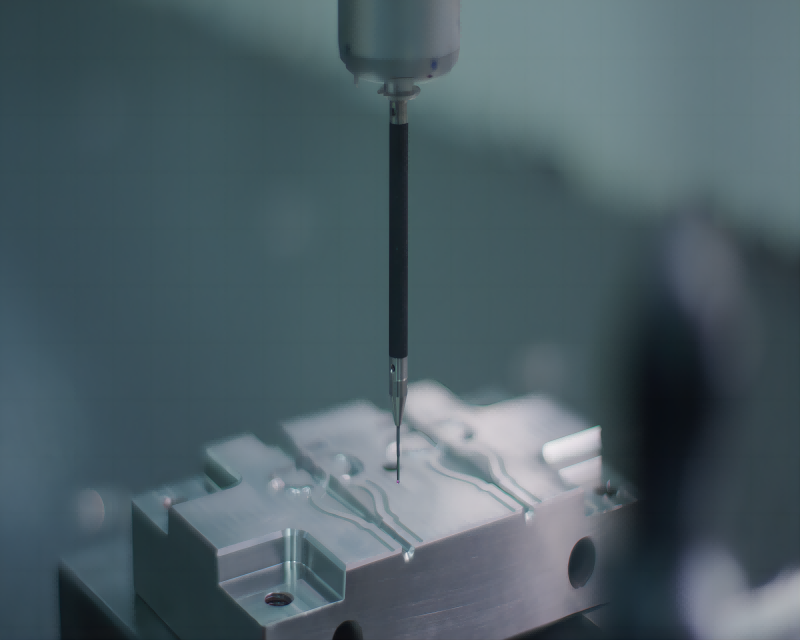

Tip Forming

Precision Medical Tubing Services Tip Forming involves shaping and forming the tips of medical-grade tubing materials to meet the specific requirements of medical device applications. The composition of the tubing used in this process varies depending on the desired properties and performance characteristics required for the medical device. Typically, medical tubing is made from biocompatible polymers such as polyethylene (PE), polyurethane (PU), polyvinyl chloride (PVC), silicone, or thermoplastic elastomers (TPE). These materials are selected for their flexibility, durability, and compatibility with bodily fluids and tissues.

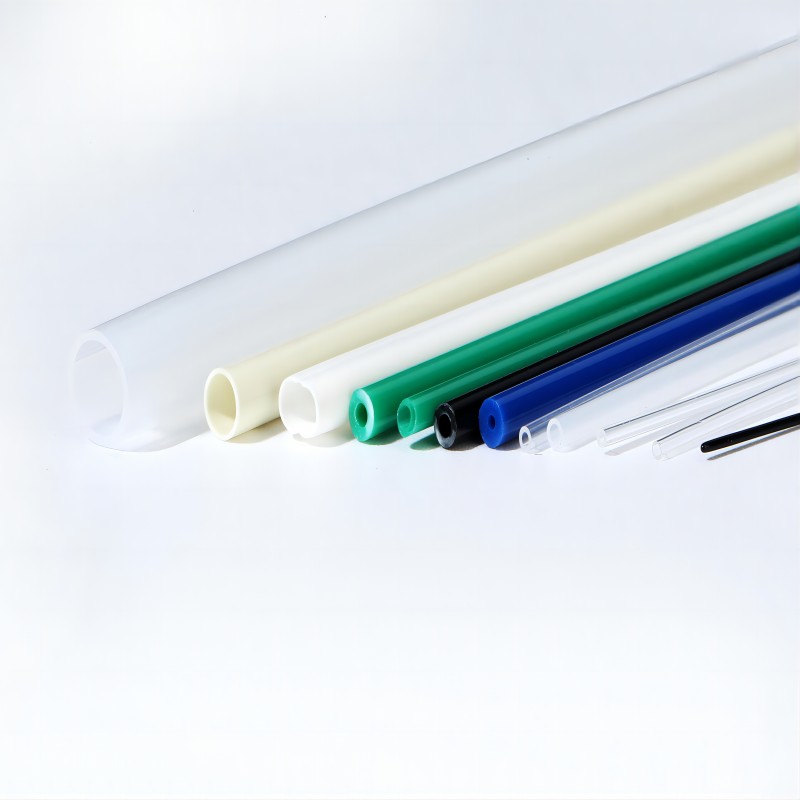

PP Tube

The PP Tube is meticulously crafted from high-quality polypropylene, a thermoplastic polymer renowned for its exceptional chemical resistance, durability, and biocompatibility. This composition ensures that the tube is safe for use within the body and can withstand the rigors of medical procedures without compromising patient safety or device performance. Employing state-of-the-art manufacturing techniques, Demax ensures uniformity in dimensions and performance, producing PP Tubes that meet the highest standards of quality and reliability. With Demax’s PP Tubes, healthcare professionals can perform medical procedures with confidence, knowing that they have a dependable and effective tool at their disposal to deliver optimal patient care.

PA Tube

The PA Tube, also referred to as a Single Lumen Tube, is a crucial component utilized in various medical settings for precise fluid delivery or instrument insertion during procedures. It serves as a conduit, ensuring the seamless transfer of fluids or the introduction of medical instruments with accuracy and reliability. Constructed from durable materials, the PA Tube is designed to withstand the rigors of medical procedures while prioritizing patient safety and comfort.