TPU Tube

Demax TPU tubes are meticulously crafted from Thermoplastic Polyurethane (TPU), a premium synthetic polymer renowned for its exceptional elasticity, durability, and resistance to abrasion, chemicals, and environmental factors. This composition ensures the tubes’ longevity and reliability, even in the most demanding conditions. Demax’s commitment to quality extends to every aspect of their manufacturing process, from sourcing the finest materials to employing advanced production techniques. The result is a TPU tube that meets stringent industry standards, providing customers with confidence and peace of mind in their critical applications. Whether in medical procedures, laboratory experiments, or industrial processes, Demax TPU tubes deliver unmatched performance and durability, making them the preferred choice for professionals across various sectors.

- Material Composition: TPU Tube ( Single Lumen Tube) are crafted from Thermoplastic Polyurethane, a synthetic polymer known for its elasticity, durability, and resistance to abrasion, chemicals, and environmental factors. This material ensures longevity and reliability in diverse operating conditions.

- Flexibility: TPU Tubes possess high flexibility, allowing them to bend and conform to various shapes and configurations without sacrificing structural integrity. This flexibility simplifies installation and enhances maneuverability in complex systems, reducing installation time and labor costs.

- Size Range: Available in a broad range of sizes, TPU Tubes cater to diverse application requirements. From small diameters suited for intricate medical procedures to larger diameters for industrial fluid handling, these tubes offer versatility to accommodate different fluid volumes and flow rates.

- Single Lumen Design: TPU Tubes feature a single lumen design with a seamless interior pathway, ensuring unobstructed fluid flow. This design is critical in applications where precise fluid control and consistency are essential, preventing blockages and maintaining optimal performance.

- Transparency: Many TPU Tubes are transparent or translucent, allowing for visual monitoring of fluid flow. This transparency facilitates real-time observation of processes, enabling operators to detect abnormalities promptly and ensure smooth operation.

| Outer Diameter | Tube Wall Thickness(mm) | ||

| Outer Diameter Specification(mm) | Outer Diameter Tolerance(mm) | Minimum Tube Wall Thickness(mm) | Tube Wall Thickness Tolerance(mm) |

| 0.5-10.0 | ±0.03 | 0.05 | ±0.03 |

- Medical: In the medical sector, it play a crucial role in applications such as catheters, IV lines, and respiratory tubing. They enable the safe and efficient delivery of fluids, medications, and gases within the body during surgical procedures, patient care, and diagnostic tests.

- Laboratory: Laboratories utilize TPU Tubes for fluid handling, chromatography, and sample analysis. Their flexibility and chemical resistance make them ideal for connecting equipment and facilitating precise fluid control in experiments and research activities.

- Industrial: Industrial processes rely on TPU Tubes for fluid transfer, chemical handling, and pneumatic systems. Their robustness and versatility ensure the smooth operation of machinery and processes in manufacturing, automotive, and other industrial sectors.

Related products

Stent delivery system Braided catheter

Establishing an access channel forinstruments to enter the body

Customizable in various sizes to meet different lesion requirements

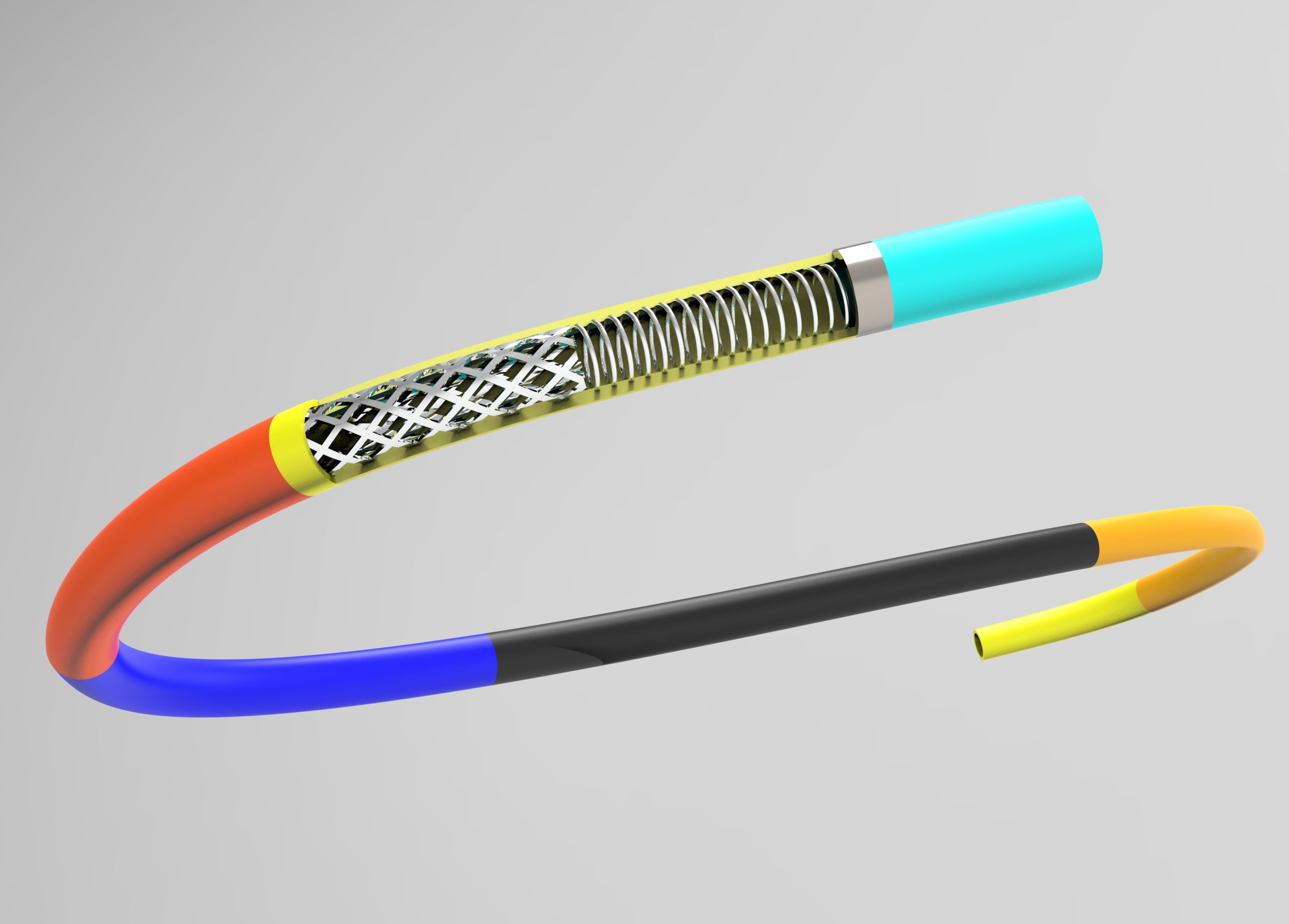

Braid & Coil Reinforcement Tube

The Demax Braid & Coil Reinforcement Tube is an innovative medical device designed to provide enhanced strength and flexibility for a wide range of medical applications. Crafted with precision and utilizing advanced materials, this reinforced tubing offers exceptional performance and reliability, making it an indispensable tool for medical professionals in various clinical settings.

Flaring

Precision Medical Tubing Services Flaring involves the precise modification of medical-grade tubing materials to create flares and expansions. The composition of the tubing used in this process varies depending on the specific requirements of the medical device and the application. Typically, medical tubing is made from biocompatible polymers such as polyethylene (PE), polyurethane (PU), polyvinyl chloride (PVC), silicone, or thermoplastic elastomers (TPE). These materials are selected for their flexibility, durability, and compatibility with bodily fluids and tissues.

Microcatheter

Features:

1. PTFE inner layer allows for smooth passage for embolic agents;

2. Optimal trackability through tortuous anatomy;

3. Available in pre-shaped tip shape configurations for vessel engagement;

4. Four shapes provides more option for clinical usage;

5. 2.0F/2.2F/2.6F/2.8F models are available;

6. Hydrophilic coating technology, smoothly through the lesion.