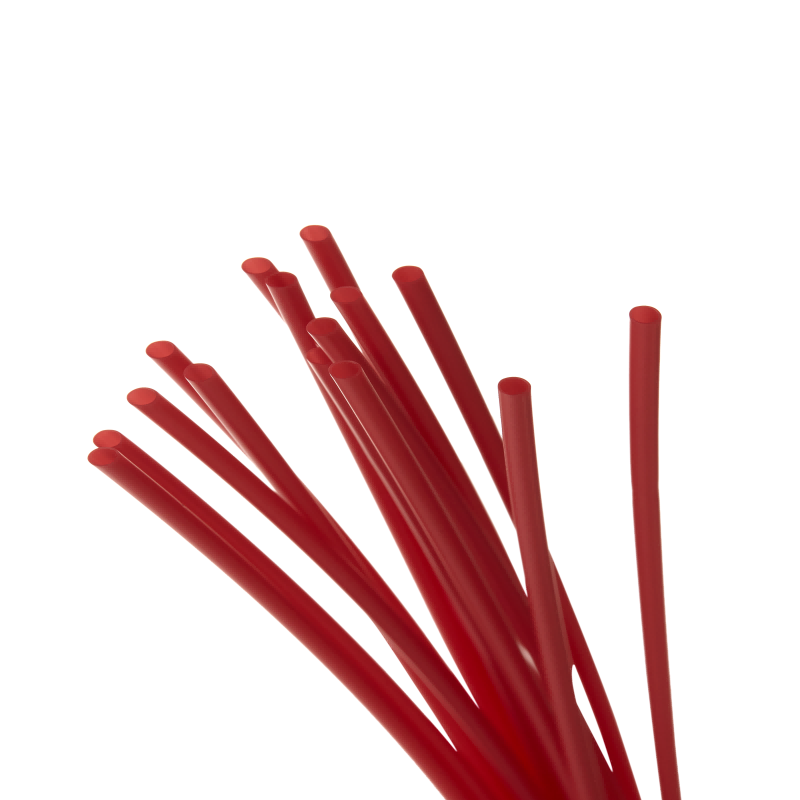

FEP Heat Shrink Tube

The FEP Heat Shrink Tube boasts a composition rooted in fluorinated ethylene propylene (FEP), a thermoplastic polymer renowned for its exceptional properties in medical applications.

FEP exhibits a unique combination of characteristics that make it ideally suited for medical tubing. Its molecular structure imparts remarkable clarity to the tubing, allowing for optimal visualization of fluids and instruments during medical procedures, essential for accurate monitoring and precise manipulation.

Features

- Lower heat shrink temperature:FEP heat shrink tubing has a lower heat shrink temperature than other fluorinated heat shrink tubing, such as PTFE, PFA

- It has better flexibility, light transmittance and high lubricity than PFA.

- The recommended shrinking temperature is 80℃-240℃. The shrinking temperature and shrinking time vary depending on the design.

- Demaxcan provide FEP heat shrink tubing with shrinkage ratios of 1.3:1, 1.6:1 and 1.8:1.

Applications

Welding of Guiding Catheter, Angiography Catheter, Micro Catheter, Guiding Sheath, Distal Access Catheter: laser welding, hot air welding, heat fusion welding, etc.Technical Parameters

- Minimum Inner Diameter Before Shrinkage:79-4.78(mm)

- Maximum Inner Diameter Before Shrinkage:69-2.92(mm)

- Tube Wall Thickness After Shrinkage:2±0.05,0.23±0.05,0.25±0.08, 0.28±0.1(mm)

- Shrink Temperature 200-230℃

- Shrink Ratios 3:1,1.6:1, 1.8:1

- Concentricity ≥90%

- Biocompatibility Conforms to ISO10993

Related products

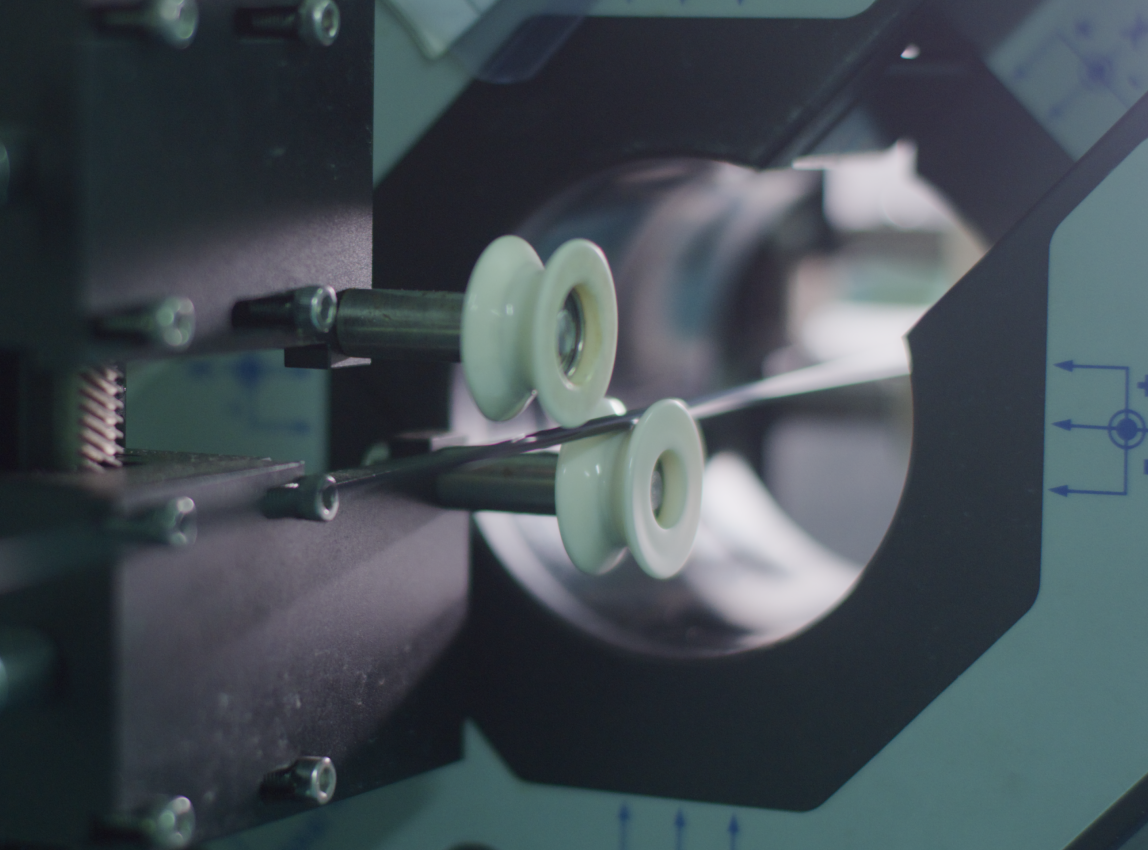

Hook Forming

Demax utilizes high-quality materials such as stainless steel or nitinol for hook forming, chosen for their exceptional mechanical properties, corrosion resistance, and biocompatibility. These materials undergo precise shaping processes to achieve intricate hook configurations tailored to specific medical device applications. With our commitment to quality and precision, Demax ensures that hook-formed components meet the rigorous demands of medical device manufacturing, contributing to the advancement of healthcare worldwide.

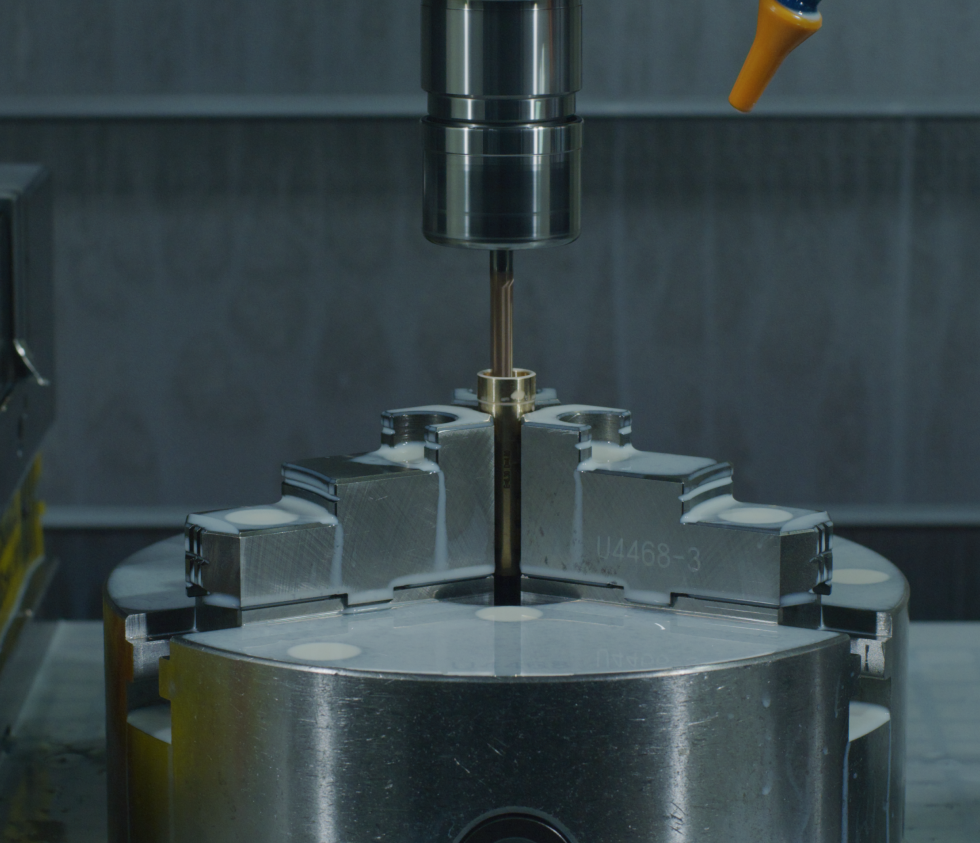

Punching

Precision Medical Tubing Services Punching from Demax involves the precise creation of perforations, holes, or patterns in medical-grade tubing using advanced punching methods and equipment. The tubing material, typically made from medical-grade polymers such as polyethylene (PE), polyurethane (PU), or silicone, is carefully selected for its biocompatibility, flexibility, and durability. During the punching process, specialized punches and dies are used to create holes of specific sizes, shapes, and configurations in the tubing, allowing for precise control over the perforation characteristics. Each punched hole is inspected and verified to ensure that it meets the required tolerances and quality standards. Demax’s expertise in precision punching ensures that punched medical tubing maintains its structural integrity, biocompatibility, and performance, meeting the demanding requirements of medical device manufacturers and healthcare professionals.

PE Tube

The PE Tube is meticulously crafted from high-quality polyethylene, a thermoplastic polymer renowned for its exceptional chemical resistance, flexibility, and biocompatibility.

The PE Tube, or Polyethylene Tube, represents a vital component in the realm of medical devices, serving as a conduit for the passage of fluids or gases within the body during various clinical procedures. Crafted from polyethylene, a resilient and biocompatible material, the PE Tube is engineered to meet the rigorous demands of medical interventions while ensuring patient safety and procedural efficacy.

Microcatheter

Features:

1. PTFE inner layer allows for smooth passage for embolic agents;

2. Optimal trackability through tortuous anatomy;

3. Available in pre-shaped tip shape configurations for vessel engagement;

4. Four shapes provides more option for clinical usage;

5. 2.0F/2.2F/2.6F/2.8F models are available;

6. Hydrophilic coating technology, smoothly through the lesion.