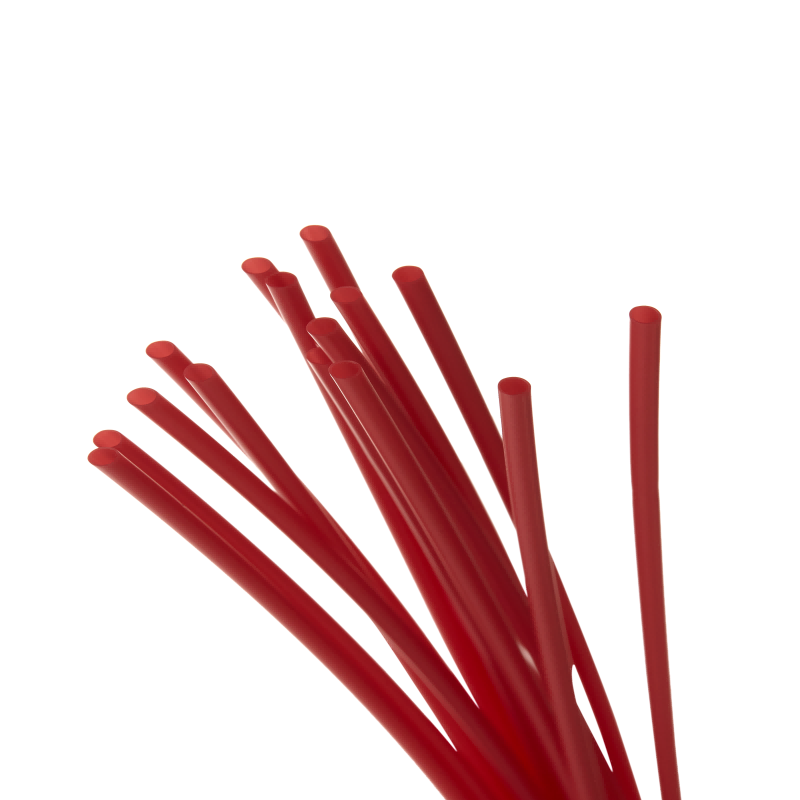

PTFE Liner

PTFE (polytetrafluoroethylene) is a synthetic fluoropolymer that is used as a liner in catheters due to its unique properties. PTFE has a very low coefficient of friction and is a highly durable material with excellent tensile strength. Catheter liners made of PTFE can withstand the stresses of use in medical devices and resist breaking or tearing.

PTFE is used as a liner in catheters because it provides a smooth, low-friction surface that helps reduce the risk of infection and tissue damage. They are also biocompatible so that most people won’t experience an allergic reaction or any negative response.

Features

Dip coating process:- Supplied in rolls, can be used for subsequent continuous production, low manufacturing cost of post-process

- The ultra-thin design improves lubricity, minimizing damage and irritation to surrounding tissues during medical instrument insertion and withdrawal.

- The outer layer can be covered with polymer materials, long shelf life, good bonding effect

Applications

- Guiding Catheters

- Deflectable Catheters

- Steered Catheters

- Device delivery systems

Technical Parameters

- Mandrel outer diameter: 0.010”~ 0.137”

- Minimum wall thickness: 0.0005”~ 0.002”

Related products

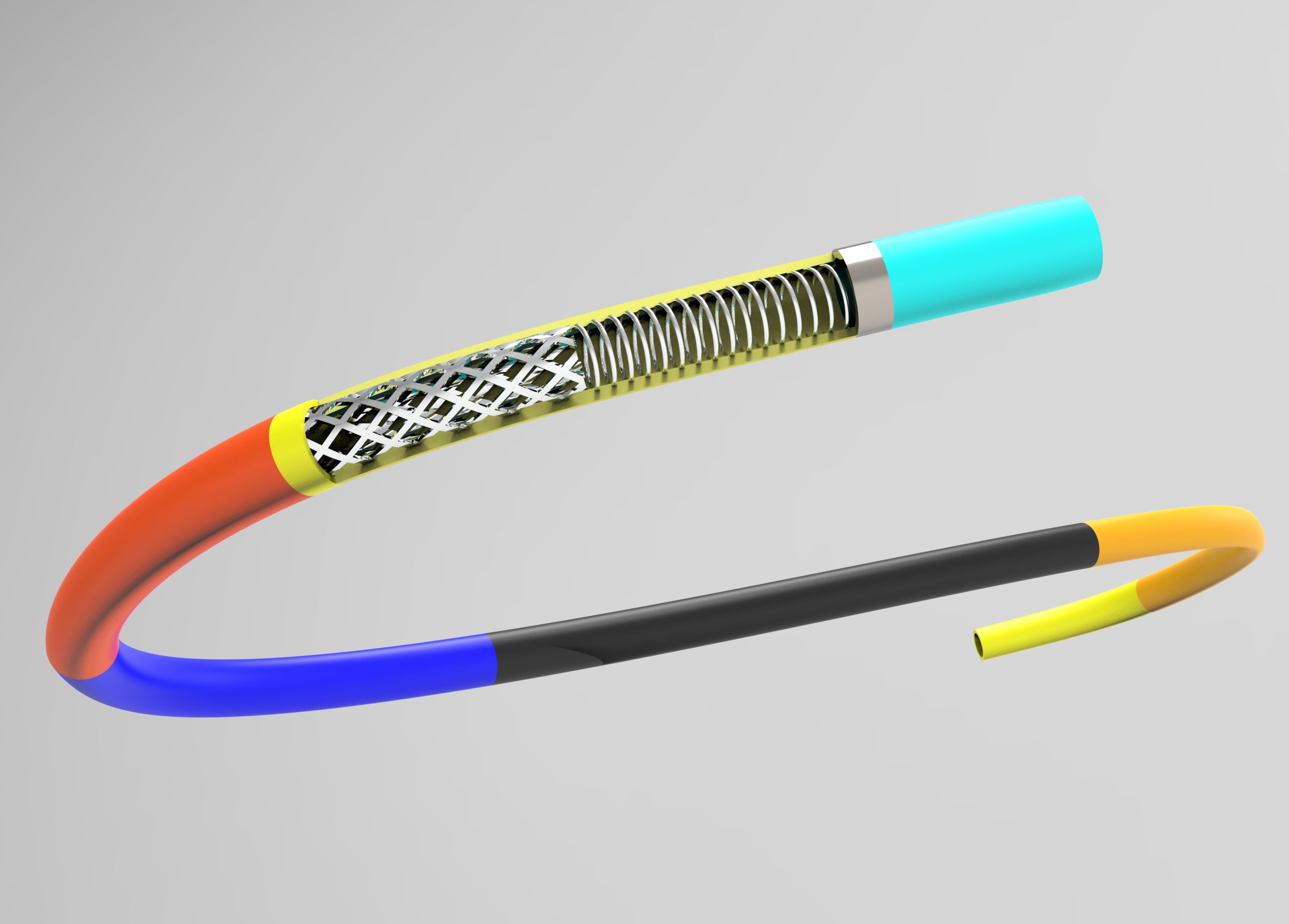

Stent delivery system Braided catheter

Establishing an access channel forinstruments to enter the body

Customizable in various sizes to meet different lesion requirements

Braid & Coil Reinforcement Tube

The Demax Braid & Coil Reinforcement Tube is an innovative medical device designed to provide enhanced strength and flexibility for a wide range of medical applications. Crafted with precision and utilizing advanced materials, this reinforced tubing offers exceptional performance and reliability, making it an indispensable tool for medical professionals in various clinical settings.

Coating

Precision Medical Tubing Services Coating from Demax involves the application of specialized coatings onto medical-grade tubing substrates to enhance their performance and functionality. These coatings may include hydrophilic coatings, hydrophobic coatings, antimicrobial coatings, drug-eluting coatings, and more, depending on the specific requirements of the medical device and application. The coating materials are carefully selected for their biocompatibility, adhesion properties, and compatibility with the substrate material to ensure optimal performance and safety. Each coating is applied using precise coating techniques to achieve uniform coverage and consistent thickness, resulting in medical tubing with enhanced lubricity, biocompatibility, and other desirable properties.

PE Tube

The PE Tube is meticulously crafted from high-quality polyethylene, a thermoplastic polymer renowned for its exceptional chemical resistance, flexibility, and biocompatibility.

The PE Tube, or Polyethylene Tube, represents a vital component in the realm of medical devices, serving as a conduit for the passage of fluids or gases within the body during various clinical procedures. Crafted from polyethylene, a resilient and biocompatible material, the PE Tube is engineered to meet the rigorous demands of medical interventions while ensuring patient safety and procedural efficacy.