In the evolving field of minimally invasive surgery and interventional medicine, Braided Catheter Shaft design plays a crucial role in enhancing navigation precision and procedural success. As a trusted manufacturer committed to advancing catheter technology, Demax has developed a high-performance Braid & Coil Reinforcement Tube that significantly improves flexibility, torque control, and overall handling performance. With our proprietary materials and customizable construction, our braided catheter shafts help medical professionals perform with greater confidence and safety.

At Demax we build every Braided Catheter Shaft with a single goal in mind: give physicians fingertip-level command inside the most delicate vessels. By weaving high-grade SUS304 or nickel-titanium filaments between medical-grade polymers, we transform raw materials into a responsive extension of the operator’s hand – a shaft that steers accurately, resists kinking, and keeps critical devices on course.

Engineering the Demax Braided Catheter Shaft for Superior Precision

Our engineering philosophy is simple: precision begins long before the catheter reaches the cath-lab. It starts on the braiding line where wire tension, pick-per-inch (PPI) density, and spindle count interact to create a perfectly balanced tube.

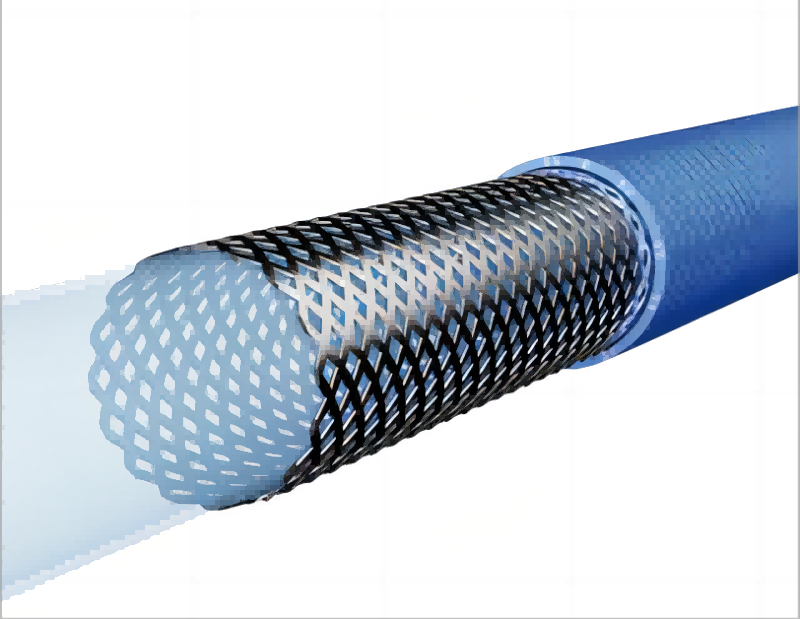

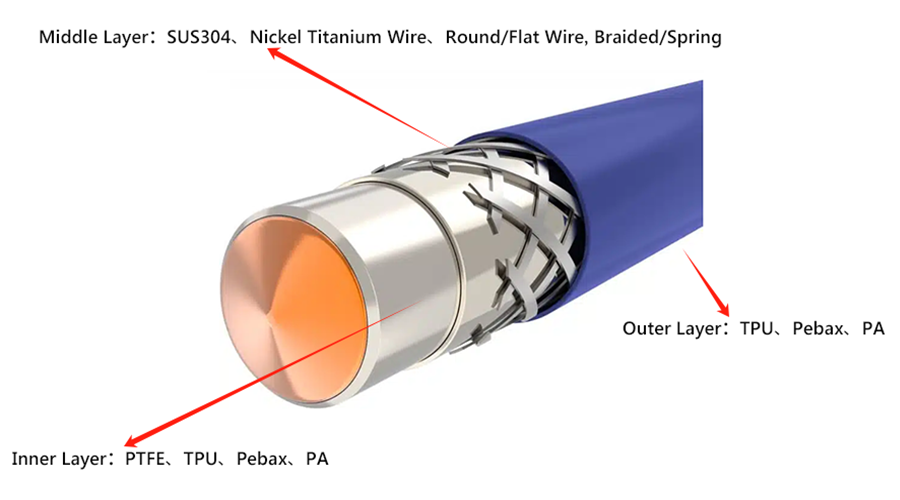

• Material Layering

We laminate three synergistic layers:

✅Outer Jacket (TPU / Pebax / PA) – delivers a low-friction, abrasion-resistant surface while accepting hydrophilic coatings.

✅Braid or Coil Reinforcement (SUS304, Nitinol, or stainless steel) – round or flat wire, 8- to 72-spindle patterns (1×1, 1×2, 2×2) give controllable torque profiles.

✅Inner Liner (PTFE / TPU / Pebax / PA) – ultra-smooth lumen maintains flow and device compatibility even at 5 – 15 mm inner diameters.

This composite keeps wall thickness within 0.07 – 0.3 mm while holding ±0.0125 mm ID and ±0.1 mm OD tolerances – tight enough to eliminate guesswork during navigation.

Beyond dimensions, our braid angle and coil pitch are tuned to balance two opposing forces: pushability and trackability. A shallower angle strengthens axial stiffness for long lesion crossings; a steeper angle enhances torsion for whip-like tip rotation. With computer-controlled machines we lock those parameters into every meter of shaft, ensuring reproducibility from batch to batch.

But numbers alone do not convey the tactile difference. Surgeons often describe the Demax shaft as “alive” – subtle wrist motions transmit instantly to the tip while the body stays resilient against crush and bend. That lively feedback reduces overcorrection, tightens catheter loops, and ultimately raises procedural confidence.

Clinical Advantages

When the guidewire must snake through a 2 mm cerebral branch or an iliac tortuosity, millimetric error is unacceptable. The Demax Braided Catheter Shaft turns design theory into bedside efficiency by delivering three concrete benefits:

✅Higher First-Pass Success – Consistent torque response lets physicians steer into ostia without repeated repositioning, shortening fluoroscopy time.

✅Lower Force, Less Trauma – A flexible distal zone paired with strong proximal support allows gentle advancement, reducing endothelial injury risk.

✅Stable Device Delivery – Stent systems, micro-coils, or embolic agents track smoothly through the PTFE liner, minimizing friction spikes that can jolt tip position.

We see these gains daily across specialties:

•Vascular Interventions: Guiding and distal access catheters maintain coaxial alignment during complex bifurcations, aiding rapid stent deployment.

•Endoscopy & Urology: Braided shafts convey irrigation and suction tools with predictable bending, protecting delicate mucosa.

•Neurosurgery & Oncology: Microcatheters navigate cerebral or tumor micro-vasculature where sub-millimeter steering defines success.

•Imaging: Contrast delivery catheters keep lumen patency under high-pressure injections for crisp CT or MR angiograms.

•Reduced Procedure Time, Improved Outcomes

Hospitals tracking key performance indicators report shorter average procedure duration when switching to Demax catheters – time reclaimed for additional cases or reduced anesthesia exposure. Patients benefit from lower contrast volume and fewer radiation minutes, while payers see cost savings tied to shorter room occupancy and complication avoidance.

Customization & Future Outlook with Demax Braided Solutions

Every anatomy, strategy, and operator style is unique. That is why Demax treats the Braided Catheter Shaft not as a one-size article but as a platform. We invite OEM partners and hospital innovators to co-design shafts that answer exact clinical questions.

• Customization Levers We Offer

✅Diameter & Wall Geometry: 5 – 15 mm ID range plus micro-wall options down to 0.07 mm for neonatal or neuro applications.

✅Braid Density & Pattern: Adjust PPI or choose 8- to 72-spindle constructions to modulate radial force.

✅Coil Spacing: Variable pitch enables hybrid shafts where proximal rigidity blends into distal suppleness.

✅Polymer Blends: Mix TPU for elasticity with Pebax for recoil or PA for high-temperature stability.

✅Surface Treatments: Hydrophilic, heparin-bonded, or drug-eluting coatings extend functional roles.

✅Packaging & Traceability: Laser-etched lot coding and sterile barrier systems meet global regulatory paths.

By integrating inline imaging and AI-driven tension control, our next-generation braiders will cut tolerance drift to near zero. We are also exploring bio-resorbable braid filaments that disappear after therapeutic life, leaving only soft polymer inside the vessel – an answer to long-term foreign-body concerns.

As minimally invasive therapy moves deeper – into peripheral CTOs, structural heart defects, and micro-oncology – navigation precision becomes mission-critical. Demax stands ready with agile R&D, expansive clean-room capacity, and a proven record of global supply. Together with clinicians and device brands we will keep pushing the boundaries of what a braided shaft can do, transforming intricate paths inside the body into straightforward, repeatable routes.

About Demax

Demax is a vertically integrated manufacturer specializing in reinforced medical tubing and catheter components for cardiovascular, neurovascular, gastrointestinal, and urological care. Our ISO-13485 facilities combine automated braiding, laser-cut hypotube, and advanced polymer extrusion under one roof, allowing rapid prototyping and scalable production. Partner with us to turn visionary ideas into market-ready devices that raise the standard of patient care – one Braided Catheter Shaft at a time.