Reinforced tubing may look like a simple plastic conduit, yet inside operating rooms and catheterization labs, it quietly prevents kinks, ruptures, and costly delays. Doctors rely on its hidden strength every time they navigate delicate vessels, flush an endoscope, or deliver contrast media under pressure. This article unpacks why reinforced tubing has become a cornerstone of procedural safety – and how our latest generation at Demax helps clinicians work faster, more gental, and with greater confidence.

The Engineered Backbone of Minimally Invasive Care

Modern procedures demand devices that twist, torque, and glide through tortuous anatomy without fail. Reinforced tubing answers this call by layering strength, flexibility, and lubricity into one slender shaft – allowing clinicians to reach, treat, and retreat without hesitation.

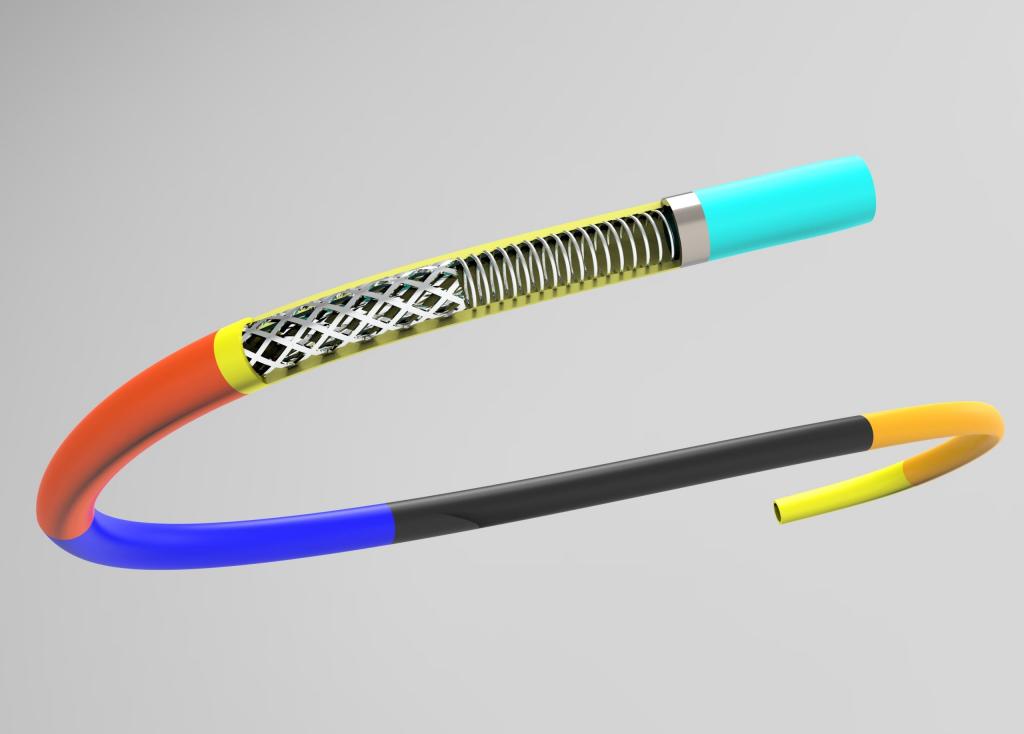

1) Composite Construction That Works in Unison

• Outer jacket – TPU, Pebax, or PA: a silky, abrasion-resistant skin that tolerates repeated insertion through valves and hemostatic seals.

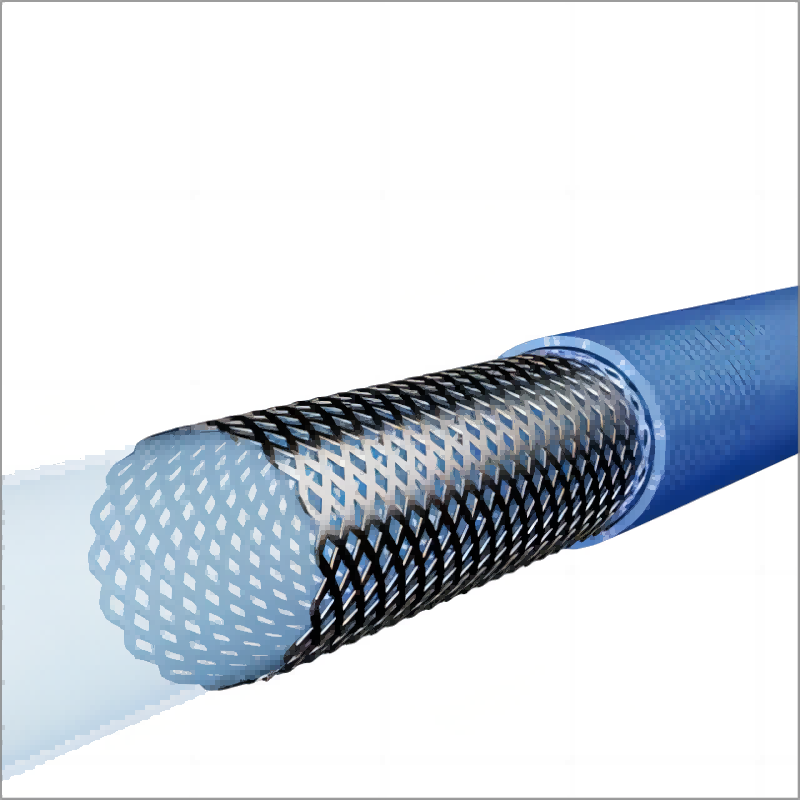

• Middle reinforcement – SUS304 or nickel-titanium braid/coil: a miniature exoskeleton that delivers precise torque while resisting bursting and buckling, even during high-pressure injections.

• Inner liner – PTFE or low-friction Pebax: an ultra-smooth lumen that keeps contrast, saline, and guidewires flowing freely, reducing pump load and thermal buildup.

Each stratum shoulders a distinct mechanical burden – much like bone, muscle, and fascia in the human body. The synergy lets the tube snap around a 180-degree bend, then advance with millimetre fidelity when the physician nudges the hub.

2) Beyond Standard Polymers

While plain PVC or PU catheters can kink or “oil-can” under stress, reinforced tubing retains its round profile under vacuum or burst conditions. Custom weave densities (8 to 72 carriers) fine-tune the balance between push and track; flat wire options lower wall thickness without sacrificing torque, preserving valuable lumen area for larger devices or faster infusion rates.

3) Why Torque and Push Matter More Than Ever

Ambulatory care pathways favour radial access and single-session interventions. To reach distal targets safely:

• High torque mirrors subtle wrist rotations, trimming fluoroscopy time and X-ray exposure.

• Consistent push force powers through calcified lesions or tortuous ureters without exchanging catheters – saving contrast, time, and patient discomfort.

• Anti-kink memory guards fragile vessels from pinch points that could dissect, perforate, or stall flow.

When reinforced tubing behaves predictably, clinicians can focus on pathology – not on coaxing equipment. The net result: shorter procedures, fewer complications, and a smoother recovery for every patient.

How Reinforced Tubing Elevates Safety at Each Phase of the Procedure

- Entry & Navigation

A reinforced sheath opens the door for guidewires and diagnostic catheters. Its thin wall (down to 0.7 mm) preserves lumen diameter, so clinicians can choose larger devices through smaller punctures, reducing bleeding risk.

- Therapeutic Delivery

During angioplasty, urology stone retrieval, or bronchoscopy, pressure spikes threaten plain polymer tubes. Reinforcement absorbs the load, preventing micro-ruptures that could release air bubbles or fragments. Studies show braided shafts tolerate burst pressures >200 psi – far beyond routine infusion demands.

- Imaging Clarity

Contrast injection must be swift yet laminar. Our PTFE-lined reinforced tubing keeps viscosity low, curbing artifact streaks on CT or MRI while shortening total injection time. Clearer images mean fewer repeats and less radiation.

- Post-Procedure Confidence

Kink resistance is not just an intra-op benefit. When patients move in recovery, coils maintain lumen patency, allowing flawless suction or irrigation until the device is removed – minimizing postoperative surprises.

Why Choose Demax Reinforced Tubing for Your Practice

At Demax, we don’t just manufacture tubing – we engineer confidence. We’ve been refining braid and coil reinforcement technologies that empower clinicians to push the boundaries of what’s possible in minimally invasive procedures. Our mission is simple: give you tools that never limit your technique.

1) Custom-Tailored to Your Technique

We understand that no two procedures – or surgeons – are the same. That’s why our reinforced tubing is highly customizable, down to the finest mechanical detail:

• Wide diameter range from 1.5 mm to 15 mm with ultra-tight ±0.0125 mm tolerances – perfect for delicate neurovascular work or robust cardiovascular interventions.

• Weave densities ranging from 8 to 72 carriers and customizable patterns like 1×1 or 2×2 – help strike the perfect balance between flexibility and torque response.

• Variable coil spacing that can be tailored to absorb pulsed flow in neurological use or add structural stiffness for peripheral access procedures.

Whether you need ultra-low friction for fast injections, or high kink-resistance for tortuous navigation, we can build tubing that adapts to your specialty – not the other way around.

2) Proven Applications Across Specialties

Our reinforced tubing supports a broad spectrum of clinical applications, trusted by leading hospitals worldwide:

✅ Cardiovascular: For guiding, diagnostic, and distal access catheters, where torque and burst resistance are critical.

✅ Endoscopy: In ERCP and gastroscopy, where tubes must maintain lumen patency through tight, twisting anatomy.

✅ Urology: Cystoscopy channels that handle frequent laser use without delaminating or rupturing.

✅ Minimally invasive surgery: Suction and irrigation lines that stay reliable, even as patient position shifts.

Each tubing design is rigorously tested to perform in real-world surgical conditions – so you can count on it when precision matters most.

3) Partnering Beyond the Purchase

At Demax, we do more than supply tubing – we co-develop solutions. As an in-house manufacturer, we offer complete OEM flexibility. Our team works with yours from concept to prototype, integrating feedback into every iteration. We conduct fatigue simulations, performance validations, and assist with documentation to accelerate regulatory clearance. With Demax reinforced tubing, you’re not just buying a component. You’re gaining a partner who understands your procedures, shares your urgency, and matches your commitment to patient safety.

Takeaway

Reinforced tubing is no longer a mere accessory; it is an active safety device woven into the fabric of every successful minimally invasive procedure. By merging cutting-edge metallurgy with medical-grade polymers, Demax delivers tubing that empowers clinicians to go farther, faster, and more safely – one silent micro-coil at a time.