Angioplasty Guide Wire handling can make a case feel calm and controlled – or tense and uncertain. In this article, we focus on simple moves that deliver reliable results. You will see how to choose the core, activate the coating, and read tip feedback under fluoroscopy. We keep each step clear and practical. At Demax we engineer each detail to support fast, confident navigation and gentle vessel interaction.

Why Hydrophilic Performance Matters In Daily Practice

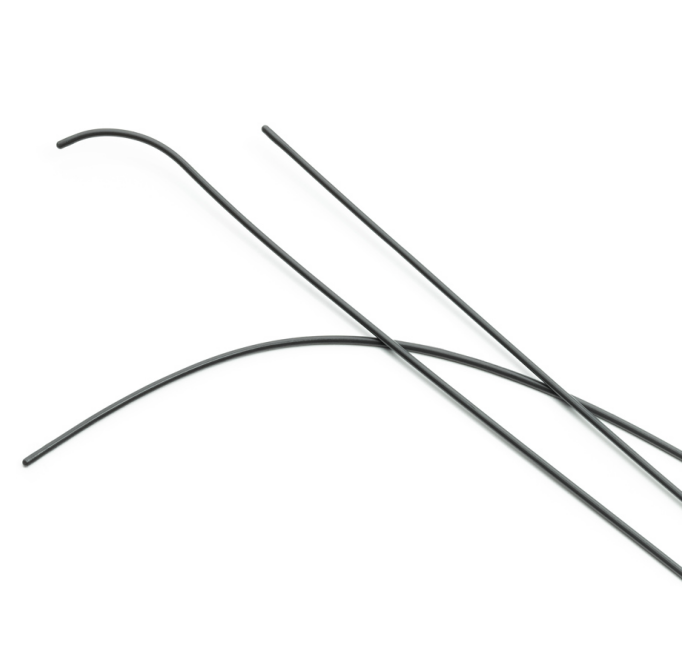

Across cath labs and IR suites, clinicians meet the same hurdles: tortuous vessels, tight stenoses, and minutes lost to wire rework. A hydrophilic Angioplasty Guide Wire addresses these pain points by pairing low-friction movement with reliable support. Demax builds this balance from the inside out. We start with a stainless-steel or nitinol core to tune pushability and track. Stainless steel brings rigidity and structural integrity for predictable advancement. Nitinol, a shape-memory alloy, adds flexibility and elastic recovery so the wire follows vessel curves without kinking under load.

- Materials And Coating: Built For Glide And Durability

The outer surface is a hydrophilic polymer layer, engineered for rapid activation when exposed to bodily fluids. This lubricious film – applied through a tightly controlled process – keeps friction consistently low along the working length. For the operator, the result is straightforward: a wire that slips through narrow or winding segments with less resistance, fewer micro-traumas, and a lower chance of unplanned exchanges. Uniform coating thickness also preserves lubricity during longer cases, helping the Angioplasty Guide Wire feel the same from access to device delivery.

- Control And Visibility: Know Where The Tip Is – Always

Low friction is only an advantage when the operator stays in command. That is why we add a distal radiopaque marker for crisp fluoroscopic feedback. Tip orientation becomes clear at a glance, which helps you confirm progress and avoid subintimal drift. A tapered tip transitions smoothly into delicate vessels and reduces entry trauma. Multiple length options support radial and femoral strategies, plus specialty approaches that benefit from extra working room.

Step-By-Step Angioplasty Guide Wire Use In Practice

This practical flow reflects how Demax engineers expect our Hydrophilic Coated Guidewire to be used for predictable, repeatable outcomes.

- Pre-Procedure Setup

Select the wire according to lesion profile and access path. If you anticipate dense plaque or need firm device support, choose a stainless-steel core. If the route is tortuous, consider nitinol for flexibility and tip recovery. Flush the sheath and guiding catheter. Wet the hydrophilic surface to fully activate lubricity. Under fluoroscopy, confirm visibility of the distal marker and inspect the tapered tip. A quick pre-case checklist reduces downstream friction – both literal and operational.

- Navigation And Crossing

Advance the Angioplasty Guide Wire with short, deliberate movements. Let the hydrophilic surface do the work; avoid excessive force. Use gentle rotation to sense the path of least resistance and keep the tip centered. If you feel growing resistance, stop. Re-wet the coating and reassess the angle rather than pushing through. This disciplined pattern – with glide, check, and re-orient – lowers the risk of endothelial damage and reduces time lost to false passages.

- Device Delivery & Exchange

Once across the lesion, stabilize the wire under fluoroscopy using the marker as your reference. Advance balloons, stents, or catheters over the wire with steady, coaxial motion. The core provides structural support for tracking while the coating reduces drag during back-and-forth adjustments. If an exchange is required, maintain wire position and hydration to preserve low friction. This approach helps you protect hard-won access and keep the case on schedule.

- Troubleshooting & Safety

When the tip biases toward the wall or progress stalls, withdraw a few millimeters, re-orient, and re-hydrate the coating. The goal is smooth progress, not brute force. Watch the marker frequently to verify intraluminal position. If you suspect spasm or micro-trauma, pause and allow the hydrophilic surface – and a moment of rest – to reduce frictional stress. Small resets now prevent bigger problems later.

Where Demax Adds Value

Clinicians ask for three things in an Angioplasty Guide Wire: predictability, gentleness, and versatility. Demax answers with material tuning, coating control, and clear fluoroscopic cues that translate into day-to-day efficiency across specialties.

In cardiology, our hydrophilic wire supports balloon and stent delivery during angioplasty, especially in tortuous coronaries where glide and tip recovery matter. In interventional radiology, it guides catheters for embolization, biopsy, or drainage with minimal push force. In urology, it assists ureteral stent placement and tract access. In gastroenterology, it helps navigate biliary and pancreatic ducts for ERCP and related interventions.

Below are selection factors we see driving consistent results in diverse labs:

• Core Construction: Choose stainless steel for robust push and device support; choose nitinol when flexibility and shape recovery are the priority.

• Hydrophilic Coating Behavior: Rapid activation and uniform coverage keep friction low, helping the wire glide through tight or winding segments.

• Radiopaque Marker: Distal visibility simplifies tip control and reduces time to confirmation during key steps.

• Tip Geometry: A smooth, tapered profile eases entry and helps minimize endothelial trauma.

• Length Options: Multiple sizes match radial, femoral, and specialty routes without compromising control.

These choices are not academic; they affect case flow. When the wire advances with fewer corrections, device delivery happens sooner, and the entire team stays in rhythm. That is how Demax turns engineering decisions – core composition, coating method, tip design – into clinical momentum.

Demax Quality Loop: Our manufacturing process focuses on coating uniformity and bond strength, because partial or uneven layers cause variable friction along the shaft. We validate radiopacity and tip geometry to maintain consistent visibility and a predictable feel during torque. This loop – design, process control, and bench testing – keeps the wire’s handling characteristics stable across production lots. For you, that means the Angioplasty Guide Wire you trust today behaves like the one you pick up next month.

Operational Impact: Reduced friction lowers the temptation to force the crossing. Better visibility shortens the time spent confirming position. A supportive core cuts down on wire exchanges. Together, these gains save minutes, protect vessels, and smooth the path to successful device delivery.

Closing Words

Ready to streamline difficult crossings with a hydrophilic Angioplasty Guide Wire designed for real-world practice? Contact Demax for specifications, evaluation samples, and technical guidance tailored to your lab’s most common scenarios. Our team will help you select the right core, tip, and length – so your next case feels precise from the first millimeter forward.