Angioplasty Guide Wire choice and technique shape real clinical results – shorter procedure time, fewer complications, and a calmer room. Speaking as Demax, a manufacturer that iterates with feedback from cath labs, we’ve learned that seemingly small decisions – core material, coating, and tip architecture – decide whether a case feels smooth or fatiguing. Below we translate that engineering into practical guidance your team can use tomorrow.

Why Wire Choice Changes Outcomes

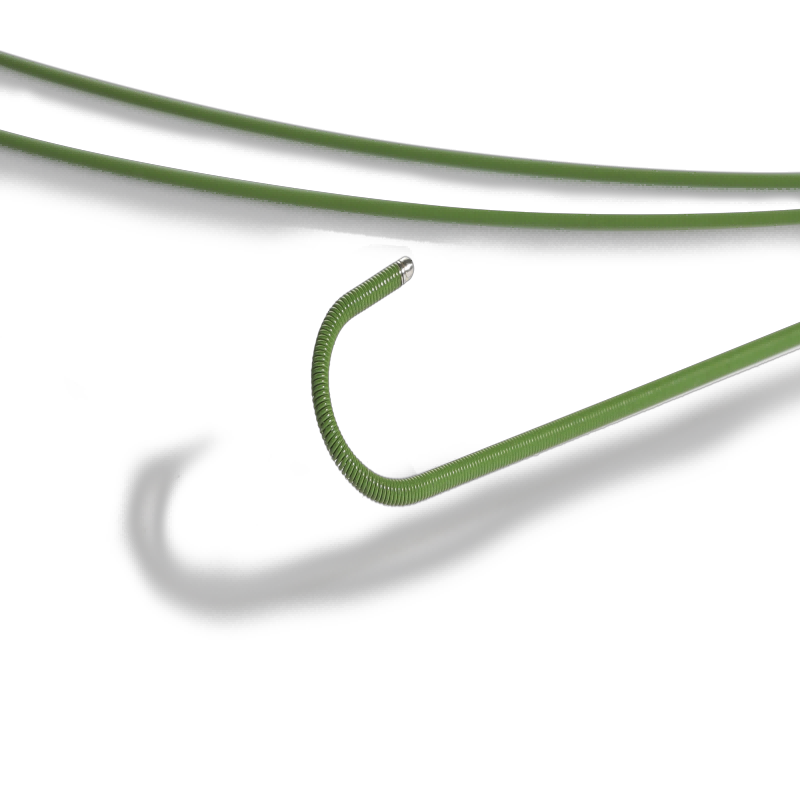

Vascular work is rarely straightforward. Tortuous anatomy, calcium, and sharp takeoff angles create a narrow margin between progress and setbacks. When a wire kinks, prolapses, or drags against the intima, the entire device train suffers. That is exactly why Demax builds its angiography wires from high-grade stainless steel or nitinol: stainless steel for crisp torque and predictable push, nitinol for resilience and kink resistance where vessels refuse to run in straight lines. Paired with a PTFE-coated spring outer layer, the shaft glides in the lumen while preserving tactile feedback – so operators feel the difference between a branch, a lesion, and the vessel wall.

Select models carry a hydrophilic surface. In tight, angulated, or chronically narrowed segments, a hydrophilic angiography guidewire reduces start-stop movement and lowers insertion forces. At the front end, a tapered tip provides controlled entry and smooth tracking, helping maintain access without traumatizing tissue. Radiopacity is tuned for visibility under fluoroscopy, which preserves situational awareness when you are operating at the edge of the field.

Sizing flexibility matters. Demax offers diameters from 0.018″ to 0.038″ and lengths from 45 cm to 300 cm (effective 90 – 300 cm) so you can build a case plan around your access route, device profile, and lesion location. Curve options – J3 and J6 – support selective cannulation; J-tip and Straight configurations align with operator preference. When wire geometry matches anatomy, procedures gain stability, and patients gain time.

Field-Tested Tips To Get More From Your Guide Wire

1) Match Diameter And Length To Control, Not Habit

Large-diameter wires can provide platform support for balloons, stents, and atherectomy. Smaller profiles enhance finesse in vulnerable or distal beds. Long approaches (e.g., radial to iliac) benefit from extended lengths to avoid unnecessary exchanges; short, focal work favors compact setups that simplify handling.

• Practical cue: Pre-map your route from puncture to target and list two backup diameters before the first image. This reduces cognitive load if the vessel behaves differently than expected.

2) Use Curves To Aim, Not Force

J3 and J6 curves alter how a tip meets the ostium. Instead of torquing harder, approach at a friendlier angle. Gentle, incremental rotations keep the tip centered and protect the endothelium while still achieving selective cannulation.

• If progress stalls: Stop. Roll back a few millimeters, re-align the catheter, and consider a hydrophilic variant if friction is the true limiter. Force fixes little and risks a lot.

3) Let The Tip And Coating Do The Work

A tapered, lubricious tip lowers the energy needed to cross tight stenoses. Hydrophilic surfaces convert stick-slip into consistent motion, which reduces micro-trauma and preserves wire position during exchanges.

• Fluoro discipline: Keep the tip in view at all times. Advance in short, deliberate strokes. If visualization fades, regain it before the next move.

4) Leverage Construction For Push – Without Losing Feel

Demax combines a stainless-steel core with a PTFE-coated spring to balance pushability and trackability. The core resists compression; the coating lowers friction inside the catheter lumen so torque transfers cleanly.

• Micro-buckling sign: A subtle “accordion” sensation. Withdraw a few millimeters, increase coaxial support, and re-engage – don’t simply push harder.

5) Design Out The Failure Modes You See Most

Common complaints we hear: early kinks, tips that deform after straightening, and rare but disruptive fractures. Our unique tip architecture tolerates multiple straightenings of the J-tip without permanent set, and an improved rod design gives more axial stiffness for reliable push while mitigating fracture risk. The goal is predictability: fewer unscheduled wire changes, fewer lost positions, and a steadier cadence in the room.

✅ Consistency Checklist (Fast Walk-Through)

• Confirm torque-device placement and grip pressure.

• Establish coaxial alignment at the ostium before advancing.

• Match guide catheter or sheath support to wire behavior – not the other way around.

• Switch early to hydrophilic when friction, not support, is holding you back.

Demax Engineering And Specs That Solve Real Pain Points

Indications & Use Cases. Demax angiography guidewires support diagnostic angiography (selective vessel cannulation and catheter placement), PCI (crossing lesions, guiding balloon and stent delivery), peripheral interventions (angioplasty, stenting, atherectomy), and neurointerventions where precise tracking in delicate cerebral vasculature is vital. Across these workflows, the wire’s job is simple: establish a stable, safe path from the puncture site to – and through – the target so other devices can do theirs.

✅ What‘s Inside The Wire.

• Structure: PTFE-coated spring outer layer over a stainless-steel core for smooth passage and dependable push.

• Diameters: 0.018″, 0.021″, 0.025″, 0.028″, 0.032″, 0.035″, 0.038″ to match vessel size and device stack.

• Effective Lengths: 90 – 300 cm (portfolio 45 – 300 cm) for varied anatomies and access strategies.

• Curves & Configurations: J-tip (J3, J6) and Straight for selective entry and straightforward crossing.

• Tip & Surface: Tapered tip for gentle insertion; optional hydrophilic coating to enhance lubricity in tight or angulated segments.

✅ How Specs Translate To The Lab

A smoother surface reduces friction inside the catheter and against the vessel, so operators spend less time managing resistance and more time advancing therapy. Increased rod stiffness stabilizes the shaft during device delivery, helping maintain position across tortuous segments. And because the J-tip can be straightened repeatedly without deformation, you can adjust tactics mid-procedure without paying the penalty of a compromised tip.

All of this rolls up to what matters most: the Angioplasty Guide Wire becomes a cooperative partner – holding access reliably, accepting torque predictably, and moving devices where they need to go with fewer surprises. When wire behavior is predictable, teams work faster, radiation time trends down, and patients experience fewer passes and less trauma.

✅ Product Fit And Selection Guide

Choosing between stainless steel and nitinol often comes down to case mix. If you need crisp torque and a firm feel for straightforward anatomy, stainless steel may be your default. If your practice sees tortuous iliacs, hostile coronaries, or neuro work where the vessel path is unforgiving, a kink-resistant nitinol guidewire can preserve shape and control deeper into the case. Layer on hydrophilic coating when friction dominates, and select J3 or J6 based on the angle and branch you need to enter.

Call To Action – Try Demax In Your Next Case Mix

Standardizing your Angioplasty Guide Wire portfolio? Evaluating options for angiography and intervention? Request a Demax evaluation kit and technical datasheet today. Our engineering team will help map diameter, length, curve, and coating to your access routes and lesion profiles – so your staff can focus on outcomes, not workarounds. Demax remains committed to quality, innovation, and patient safety. Every wire is produced under rigorous controls to deliver the navigational accuracy, flexibility, and radiopacity clinicians expect – case after case.