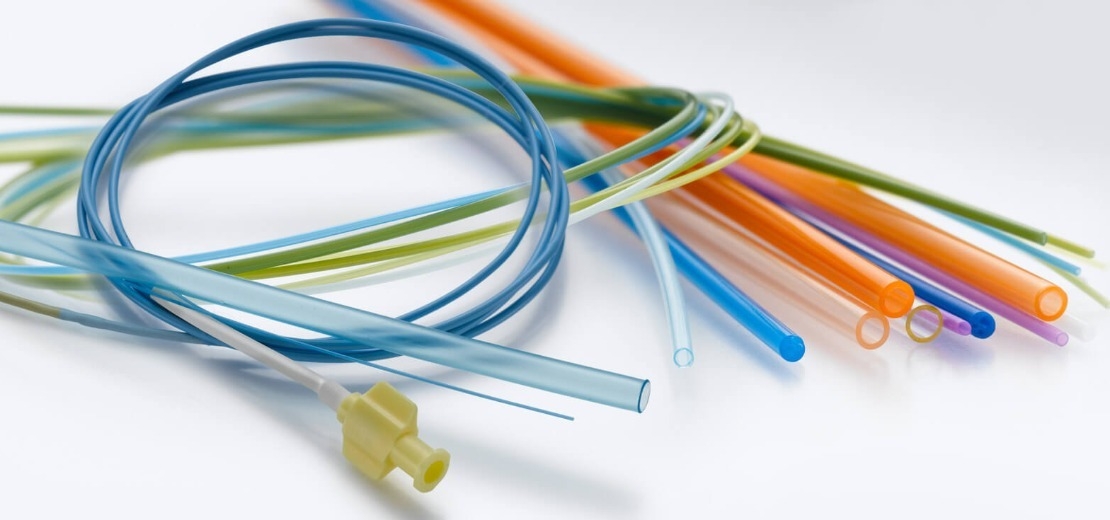

The medical tubing industry has experienced steady growth in recent years, and extrusion technology remains at the core of this development. Medical extrusion tubing is used in a wide range of applications, from intravenous lines to catheters and drug delivery systems. As healthcare needs evolve and technology advances, the extrusion medical tubing market continues to shift, shaped by innovation, regulation, and global demand.

One of the key trends driving the market is the growing use of minimally invasive surgical procedures. These procedures often require specialized tubing that can navigate the human body with precision and safety. Extruded tubing is ideal for this purpose due to its flexibility, thin walls, and ability to carry fluids or devices. As hospitals and surgical centers increasingly favor less invasive techniques, the demand for high-performance medical tubing grows in parallel.

Another notable shift is the increasing adoption of advanced materials. While traditional materials like PVC and silicone remain widely used, newer options such as thermoplastic elastomers (TPE), polyether ether ketone (PEEK), and fluoropolymers are gaining popularity. These materials offer improved chemical resistance, biocompatibility, and durability, making them more suitable for long-term or demanding medical uses. Manufacturers are investing in material science to meet stricter safety standards and performance expectations.

In addition, environmental and regulatory pressures are pushing the market toward sustainable solutions. Many medical device companies are seeking alternatives to PVC due to concerns over plasticizers and environmental impact. This is prompting innovation in biodegradable or recyclable tubing options, though these alternatives are still under development and not yet widely adopted.

A few more trends are worth highlighting:

✅ Customization and precision: Manufacturers are focusing on producing highly customized tubing to meet specific client needs, including multi-lumen and co-extruded designs.

✅ Automation and digital control: Advances in extrusion equipment, including real-time monitoring and control systems, are improving quality and efficiency.

✅ Global expansion: Emerging markets in Asia-Pacific and Latin America are witnessing increased investment in healthcare infrastructure, boosting demand for medical tubing.

Overall, the extrusion medical tubing market is evolving with changing medical practices, material advancements, and regulatory shifts. Staying informed about these trends is essential for manufacturers, suppliers, and healthcare professionals aiming to remain competitive and compliant in a fast-changing environment.

At Demax, we have a deep understanding of the precision and quality required in manufacturing medical tubing. We combine advanced materials, proprietary extrusion techniques, and stringent quality controls to develop tubing solutions that meet the evolving needs of OEM and ODM partners globally. Unlike OEM providers, we offer full-cycle ODM services – from concept development and prototyping to final product manufacturing and regulatory support.

✔ Precision control of lumen size and wall thickness

✔ Multi-layer and multi-lumen tubing capabilities

✔ Compatibility with a range of biocompatible materials

✔ Custom formulations and coatings for specific use cases

With our in-house R&D, we are continually improving the performance and safety of our tubing solutions to meet the changing demands of medical professionals and patients.

Innovations Reshaping the Extrusion Medical Tubing Market

Advancements in materials and manufacturing processes are at the heart of current market trends. Medical device manufacturers are now looking beyond basic compliance; they want smarter, stronger, and more versatile tubing.

- Smart Manufacturing and Real-Time Monitoring

At Demax, we’ve built smart production lines using the latest connectivity technologies. These lines offer real-time production data and process monitoring, which enhances consistency and speeds up production without compromising on quality.

- Material Innovation

From fluoropolymers and thermoplastic elastomers to silicone blends, material development is a major focus. Our R&D team works across disciplines – biology, mechanics, and material science – to develop custom polymer blends that offer:

✅ Enhanced flexibility and kink resistance

✅ Chemical resistance for drug compatibility

✅ Biocompatibility to meet regulatory standards

✅ Strength and durability for long-term use

- Customization and Multi-Layer Tubing

Multi-layer extrusion allows for complex tubing structures with different inner and outer properties. For example, the inner layer may be optimized for drug delivery while the outer layer offers tactile grip or UV protection.

We’ve engineered custom tubing for a variety of applications including:

• Neurovascular intervention systems

• Coronary artery diagnostic devices

• Peripheral vascular access devices

The capability to produce precise micro-extrusions and multi-lumen configurations positions Demax as a preferred partner for innovative and highly specialized medical device projects.

- How Demax Leads the ODM Transformation in Medical Tubing

As a full-service ODM provider, Demax offers end-to-end capabilities in medical product development. Our approach is not just about manufacturing but about innovation, collaboration, and long-term partnership. We don’t just build what you design – we help you design what should be built.

Why Partner with Demax?

✔ Strong R&D Foundation

With a 30,000-square-meter facility and Class 10,000 / Class 100,000 cleanrooms, our infrastructure supports large-scale production with premium standards. Our experienced engineers and scientists are constantly pushing the boundaries of tubing performance, biocompatibility, and cost-efficiency.

✔ Rapid Prototyping & Verification

We help our partners turn ideas into working prototypes with speed and precision. Each project goes through a structured verification process under ISO 13485 and ISO 9001 standards, ensuring regulatory readiness from day one.

✔ End-to-End Production and Quality Control

We support automation, semi-automation, and traditional processes – all under one roof. From raw materials to final packaging, every step is traceable and controlled to the highest standards. We also offer customized inspection, testing, and coating solutions to fit client-specific needs.

✔ Global Reach and Reputation

With a multilingual team and global sales network, Demax holds a 30% market share in coronary artery accessories across several international markets. Our quality, reliability, and customer service set us apart.

We are proud to contribute to global medical innovation by supplying high-performance extrusion medical tubing and related device components. Our long-term commitment is clear: we don’t just meet the industry standard – we aim to raise it.

Closing Words

The extrusion medical tubing market is undergoing a transformation shaped by technology, materials, and the growing demand for advanced healthcare solutions. At Demax, we’re not just observing these trends – we’re leading them. Whether you’re designing the next generation of catheters or developing innovative delivery systems, our expertise and full-spectrum ODM support can help bring your vision to life. Let’s build the future of healthcare together – one extrusion at a time.