What is a PU braided high-pressure hose Hose?

A PU braid high-pressure line is an example of a reinforced hose; this one is made out of Polyurethane (PU) because of its superior abrasion resistance as well as its strength. The hose is reinforced with a braid of polyester/nylon which further increases the pressure and durability of the hose. Such hoses are used in industries that require the transfer of fluids or air under high pressure, in pneumatics, fluid transfer, hydraulic applications, and other similar work. PU braided hoses offer the flexibility of polyurethane along with the stiffness of the braided reinforcement. This synergistic blend makes them resistant to kinks, abrasion, and weathering making the hoses suitable for outdoor and indoor use.

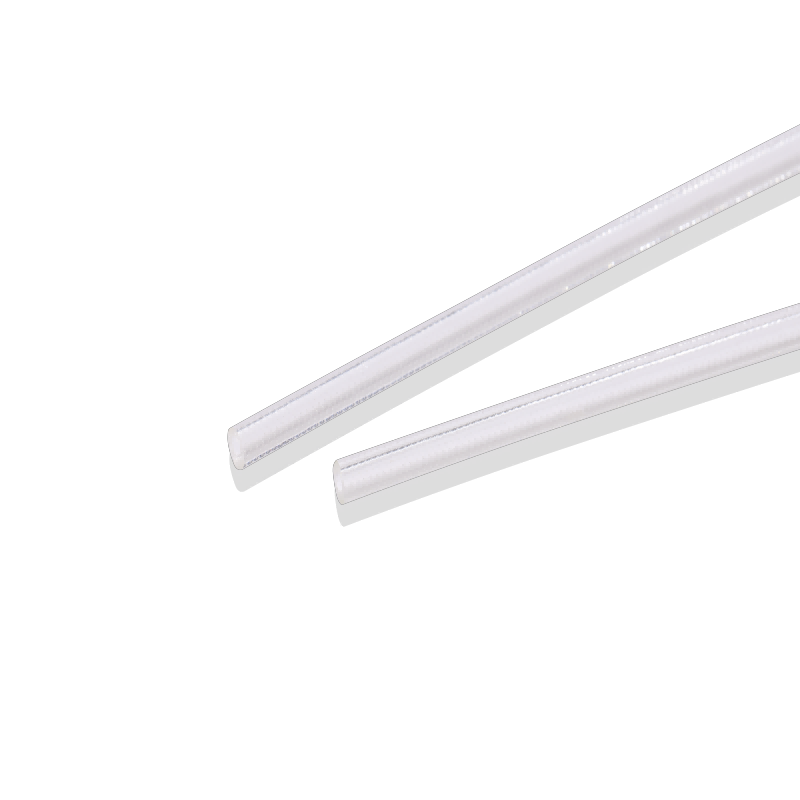

Demax PU Braided Tube: High-Performance Polyurethane Tubing

Demax PU Braided Tube is a high-pressure polyurethane tubing meant for more demanding applications. It is made of Polyurethane (PU) which is a high-performance polymer with excellent mechanical properties, and chemical and abrasion resistance. It is most useful in industries that depend on reliable fluid and air transfer, making it compatible for industrial as well as medical purposes.

Enhanced Kinking and Collapsing Strength

Demax PU Braided Tube has increased strength with a knitted casing, resisting kinking and collapsing under pressure. This braided polyurethane hose is suitable for high-pressure conditions and is ideal for use in pneumatic systems, air tools, and other demanding industrial processes.

Safe and Biocompatible for medical use

Demax PU Braided Tube is a medical-grade product that is manufactured with biocompatibility standards ensuring patient safety. Its latex, phthalate, and toxic-free nature mitigate the risk of adverse reactions or complications. Therefore, it is suitable for use in medical devices like fluid transfer and pneumatic systems.

Key Features

• High strength and abrasion resistance

• Kink resistant and flexible

• Biocompatible and latex free

Key Characteristics of PU braid high-pressure line

While keeping in mind discussing a PU braided high pressureine, the following features are the most relevant.

Durability and Strength

A high-strength PU material, braided reinforcement, hoops, and other details make these hoses extremely durable. These hoses may be used for high pressure, abrasion-intensive work, or for fluid transfer under extreme temperatures, they will provide long service life.

Flexibility

Regardless of enduring conditions, PU braid hoses remain flexible enough to aid installation and handling requirements. This feature makes PU braid hoses ideal for use in confined places or tight spaces.

Abrasion Resistance

The outer braided layer provides these hoses with abrasion resistance and helps avoid needless damage. This feature allows these hoses to be used on rough surfaces or surroundings where the hose undergoes constant motion.

Kink Resistance

Among the many properties of PU braided hoses, kink resistance makes them stand out. The braided reinforcement allows unrestricted movement of the hose throughout its length, thus preventing it from kinking or collapsing under high pressure.

Weather and Temperature Resistance

A significant advantage of PU braid hoses is their capability to work efficiently over a wide range of temperatures and environmental conditions. PU braided hoses are weather resistant perform well under both hot and cold temperatures suitable for outdoor industrial purposes.

Applications of PU Braid High-Pressure

They have broad versatility and can be found in a wide range of industries. Some of these include:

Pneumatic Systems

Pneumatic PU braided hoses are widely utilized in the air compression systems, robotics, and automated systems sectors. Flexibility and tolerance to high pressure make them ideal for air tool hoses and paint spray hoses for aerosol paints.

Hydraulic Systems

PU braided hoses used in hydraulics are not as popular as rubber or thermoplastic hoses, but they are gaining more widespread use for specific hydraulic applications because of their lightweight and ability to withstand high pressure.

Fluid Transfer

Reinforced PU hoses are excellent when it comes to transferring fluids regardless of whether it’s chemicals, oils, or water-based fluids. Their abrasion and oil-resistant properties guarantee safe and efficient transport.

Industrial Equipment

From high-pressure flexible hoses for manufacturing to more specialized applications in robotics and automated systems, these hoses are integral to the effective functioning of complex machinery.

Air Compressors

Air compressor hoses are PU braided owing to the flexibility and abrasion resistance offered by these types of hoses. These attributes allow reliable air transmission throughout the compressor while standing up to wear and tear over time.

Advantages of Using PU braided high-pressure hose

Enhanced Pressure Resistance

Compared to other types of hoses, high-PU high-pressure hose hoses achieve broad ranges of pressure while retaining flexibility and strength. This makes them suitable for highly demanding applications like hydraulic systems or paint spray systems.

Lightweight Design

Even in comparison to metal or rubber hoses, PU braided hoses are lighter and bestow great strength. This characteristic makes them easy to manage and position during installation, particularly in confined spaces.

Cost-Effective

At first, it is more expensive than standard hoses, but the durability and lifespan of PU braid hoses make it cost-effective in the long run. Withstand abrasion, kinks, wear and tear, the hose reduces the overall costs incurred from maintenance and replacement.

Eco-Friendly

The recycling nature of polyurethane makes PU braided hoses a more eco-friendly choice than other materials which are harder to recycle.

How to Best Choose a PU Braid High-Pressure?

Keeping the following in mind will help you choose the best-braided PU high-pressure hose for your specific needs:

Pressure Rating

Always check that the hose pressure rating is in accordance with your system’s requirements. Whether it is a pneumatic or fluid transfer system, it is critical that the hose selected is within acceptable pressure limits.

Material Compatibility

For applications that come into contact with chemicals or oils, select a PU braided hose with oil-protective properties. Also, ensure that the hose is made to endure extreme temperatures for high heat scenarios.

Length and Degree of Movement

Alongside a specified length, consider the flexibility of the hose for movement and its ability to reach desirable locations along the planned pathways.

Custom Requirements Based on Industries

Custom-tailor your gear depending on the specific industry you are operating in. As an illustration, paint spray hoses need to be easy to clean and abrasion-resistant, while robotics hoses ought to be extremely flexible and wear-resistant.

Conclusion

All in all, the PU braid high-pressure line offers a solution for many different industries as they are flexible, resistant to abrasion, high pressure tolerant, and useful from pneumatic systems to fluid transfer. These are flexible and can withstand a great deal of stress. With the right PU braided hose, you can be sure that no matter how harsh the conditions, the performance will not be affected, and safety, durability, performance, and reliability will always be ensured. From reinforced polyurethane pressure hoses to high pressure air hoses, PU braided hoses serve all industrial requirements seamlessly. Visit Demax for more details on our wide variety of PU braided high-pressure hose.