A Structural Heart Delivery System must slide, bend, and reposition inside vessels that can be tortuous, calcified, or highly delicate. At Demax, we believe the single most decisive factor in achieving this smooth, predictable motion is the quality of the hydrophilic coating applied to every guidewire, catheter introducer, and delivery shaft that exits our cleanrooms. In the following analysis we explain why the coating matters, how we engineer it, and where the technology is headed – all from an original-equipment-manufacturer’s viewpoint.

Advancing Patient Outcomes with Hydrophilic Coatings

Modern transcatheter valve repair and replacement procedures depend on perfect control. When a cardiologist advances a guidewire through the aortic arch or manipulates a delivery catheter across the mitral valve, any hesitation can increase fluoroscopy time, create endothelial trauma, or even trigger embolic events. Hydrophilic coatings mitigate these risks by binding to water molecules the instant they contact blood or saline, forming a micro-thin hydration layer that lowers the coefficient of friction by up to 80 % compared with uncoated stainless-steel shafts.

• Material Science Behind the Coating

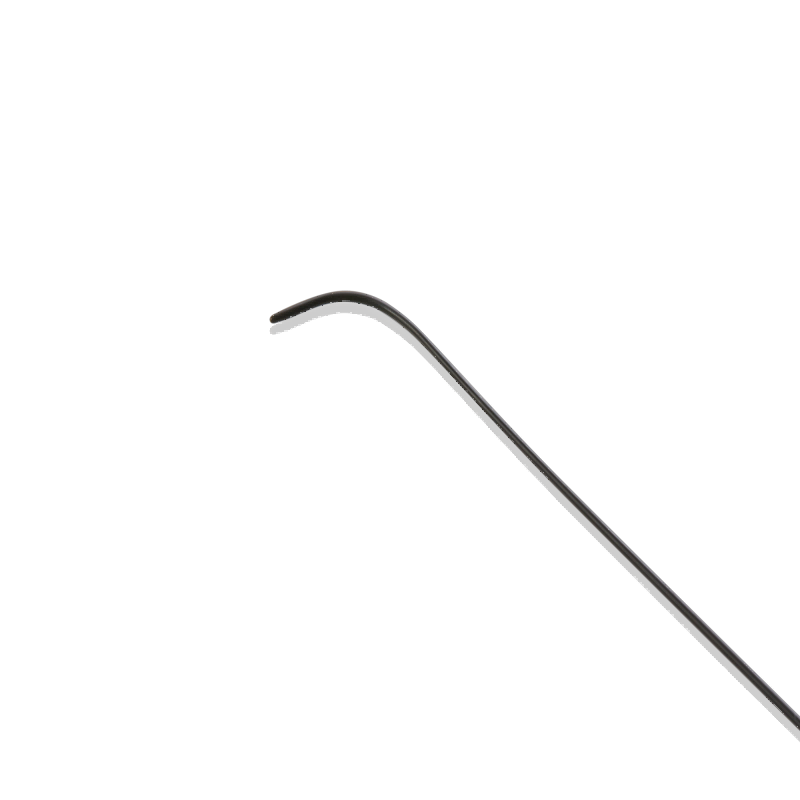

Inside every Demax guidewire lies a dual-core structure. Stainless-steel segments deliver pushability proximal to the operator’s hand, while nitinol offers super-elastic flexibility at the distal region. Over this metallic backbone we apply a covalently bonded PTFE-based polymer matrix only 3 – 5 µm thick. The chemistry may sound esoteric, but the clinical benefits are practical:

• The hydration layer conforms instantly to vessel curvature, minimizing shear stress.

• Surface energy remains low even after repeated repositioning, reducing platelet activation.

The coating’s microscopic “lock & key” anchoring technique prevents flaking, so lubricity lasts for procedures that can exceed two hours. Crucially, the polymer chosen is radio-transparent, so it never interferes with the marker bands that show the operator where the tip is.

Demax Engineering Excellence in Structural Heart Delivery Systems

From raw-material receipt to final pouch sealing, every Demax Structural Heart Delivery System moves through a vertically integrated quality chain. We machine, coat, and laser-weld under a single roof, enabling real-time feedback loops between R&D, production engineering, and in-process quality control.

✅ Zero-flaw hydrophilic coating line

• Fully automated dip & cure cycles with humidity control < 35 % RH

• Inline optical inspection at 20 µm resolution to detect pinholes or drips

✅ Balanced mechanical profile

• Proximal 304 SS for push; distal nitinol for kink resistance

• Laser-cut taper transition removes abrupt stiffness changes

✅ Radiopaque confidence

• Platinum-iridium tip coils and markers visible under low-dose fluoroscopy

• Optional distal J-tip for atraumatic entry

✅ Clinical versatility

• Diameters from 0.014” to 0.038” and lengths up to 300 cm

• Straight, angled, and shapable tips to accommodate aortic, mitral, or tricuspid approaches

Our coating line is ISO 13485 and cGMP compliant, backed by biocompatibility data according to ISO 10993-5, -10, and -11. Each production lot undergoes extractables/leachables screening and a simulated-use friction test in heparinized porcine blood. Only batches that pass a 10 % coefficient-of-variation threshold move forward to EtO sterilization.

• Quality Control & Compliance

Regulatory dossiers can stall if coating uniformity data are inconsistent. By combining gas-chromatography solvent-extraction studies with high-speed dynamic coefficient-of-friction mapping, Demax offers post-market surveillance data that stand up to FDA and CE-MDR scrutiny. For OEM customers, we supply:

• Master Access File cross-references

• Shelf-life kinetics of lubricity decay, plotted with 95 % confidence intervals

This transparency shortens time-to-clearance in competitive markets, letting our partners launch faster and keep pace with evolving transcatheter indications.

Future Horizons and Clinical Value

Looking ahead, the next generation of Structural Heart Delivery Systems will require even tighter navigation through alternative access routes, such as trans-septal, trans-apical, and transcaval. Hydrophilic coatings will therefore serve as enabling technology for three strategic trends:

• Miniaturization without performance loss. Lower French sizes cut vascular complications but raise friction. Ultra-thin hydrophilic layers help reclaim glide without enlarging profiles.

• Integration with smart feedback. Embedding micro-sensors for real-time pressure or flow monitoring demands coatings that remain electrically inert yet mechanically robust.

• Extended procedural use. As combined therapies – valve repair plus left-atrial appendage closure, for example – become standard, devices stay in the body longer. Coatings will need validated lubricity beyond four hours.

From our perspective at Demax, success hinges on co-development. We already collaborate with leading valve OEMs to tailor hydrophilic formulas that match their proprietary PTFE grafts and nitinol frames. Early in vitro results show a reduction in deployment time when our premium coating is paired with their self-expanding platform – time that translates directly into shorter anesthesia exposure for patients and lower cath-lab turnover costs for hospitals.

Real-World Economics

Hospitals increasingly evaluate new technology via total cost of care rather than unit price. Hydrophilic coatings influence this calculus in several ways:

• Lower contrast usage. Faster device travel reduces need for roadmap injections, limiting nephrotoxic contrast exposure and expensive post-op dialysis.

• Shorter fluoroscopy exposure. A mean reduction of 3.1 minutes per case cuts radiation-induced complications and compliance penalties.

• Fewer accessory tools. A truly lubricious guidewire decreases reliance on torquers or secondary support wires, simplifying inventories.

When multiplied across the 400 000 structural heart cases projected globally for 2026, these micro-savings become macro-advantages for healthcare systems.

Key Takeaways

Hydrophilic coatings are no longer a “nice-to-have” feature but the pivot around which modern Structural Heart Delivery Systems revolve. By investing in material science, manufacturing precision, and collaborative validation, Demax delivers devices that glide when others grind – helping interventionalists reach the target anatomy swiftly, safely, and consistently. Whether you require a ready-to-label guidewire or a fully bespoke delivery catheter, our teams stand ready to engineer the coating advantage that turns procedural ambition into predictable clinical reality.