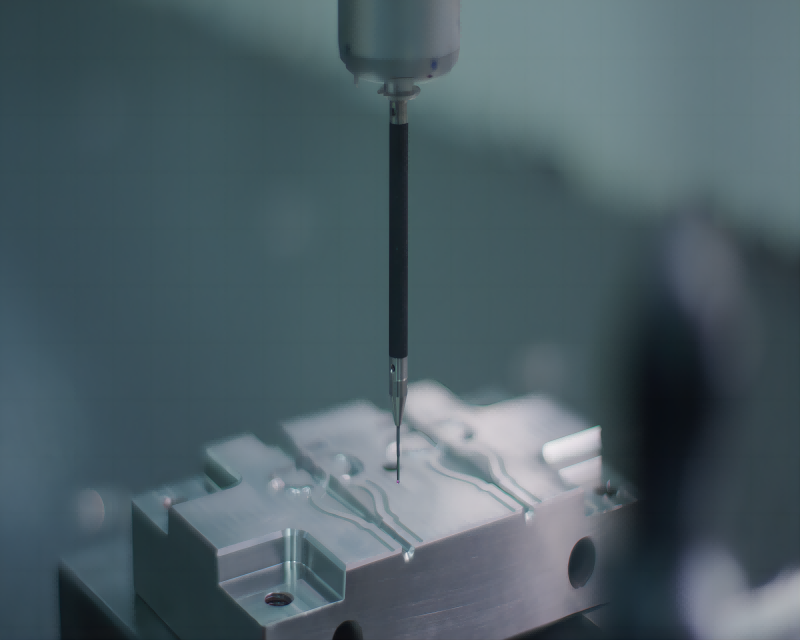

Tip Forming

Precision Medical Tubing Services Tip Forming involves shaping and forming the tips of medical-grade tubing materials to meet the specific requirements of medical device applications. The composition of the tubing used in this process varies depending on the desired properties and performance characteristics required for the medical device. Typically, medical tubing is made from biocompatible polymers such as polyethylene (PE), polyurethane (PU), polyvinyl chloride (PVC), silicone, or thermoplastic elastomers (TPE). These materials are selected for their flexibility, durability, and compatibility with bodily fluids and tissues.

- Tip Shapes: Demax offers a variety of tip shapes to suit different medical device requirements, including tapered tips, rounded tips, bullet tips, and custom-shaped tips. We can create tips with precise dimensions and angles to meet your application needs.

- Tubing Compatibility: Our tip forming services are compatible with a wide range of medical-grade tubing materials, including polyethylene (PE), polyurethane (PU), polyvinyl chloride (PVC), silicone, and more. We ensure that the tip forming process maintains the integrity and properties of the tubing material, preserving biocompatibility and performance.

- Tolerance and Accuracy: Demax maintains tight tolerances and high levels of accuracy in the tip forming process, ensuring that the dimensions and geometry of the tips are consistent and precise. Our advanced equipment and quality control measures guarantee uniformity and reliability in formed medical tubing tips.

- Catheters: Formed tubing tips are commonly used in catheter assemblies to facilitate smooth insertion, navigation, and positioning within the body’s natural cavities.

- Endoscopic Devices: Formed tubing tips are utilized in endoscopic instruments for improved maneuverability, visualization, and control during minimally invasive procedures.

- Guidewires: Formed tubing tips serve as components in guidewires to facilitate navigation through blood vessels and other anatomical structures during diagnostic and interventional procedures.

- Biopsy Devices: Formed tubing tips are employed in biopsy forceps and other tissue sampling devices to enhance precision and control during tissue collection procedures.

Related products

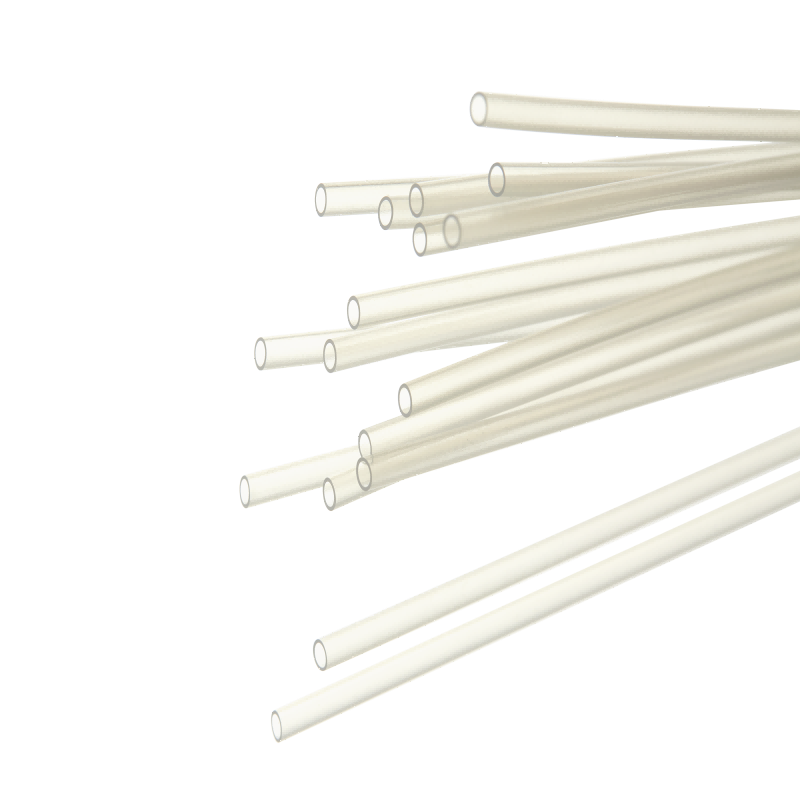

ETFE Tube

ETFE tubes manufactured by Demax are crafted from high-quality ethylene tetrafluoroethylene (ETFE) polymer.

This fluoropolymer material offers exceptional chemical resistance, mechanical strength, and biocompatibility, making it ideal for medical device applications.

ETFE tubes undergo precise extrusion processes to achieve consistent dimensions, smooth surfaces, and reliable performance in medical settings.

PE Tube

The PE Tube is meticulously crafted from high-quality polyethylene, a thermoplastic polymer renowned for its exceptional chemical resistance, flexibility, and biocompatibility.

The PE Tube, or Polyethylene Tube, represents a vital component in the realm of medical devices, serving as a conduit for the passage of fluids or gases within the body during various clinical procedures. Crafted from polyethylene, a resilient and biocompatible material, the PE Tube is engineered to meet the rigorous demands of medical interventions while ensuring patient safety and procedural efficacy.

Pebax Tube

Pebax tubing is composed of a blend of thermoplastic elastomers, typically consisting of polyether and polyamide segments. This unique composition imparts Pebax tubing with its distinctive combination of flexibility, durability, and biocompatibility, making it an excellent choice for medical tubing applications.

TPU Tube

Demax TPU tubes are meticulously crafted from Thermoplastic Polyurethane (TPU), a premium synthetic polymer renowned for its exceptional elasticity, durability, and resistance to abrasion, chemicals, and environmental factors. This composition ensures the tubes’ longevity and reliability, even in the most demanding conditions. Demax’s commitment to quality extends to every aspect of their manufacturing process, from sourcing the finest materials to employing advanced production techniques. The result is a TPU tube that meets stringent industry standards, providing customers with confidence and peace of mind in their critical applications. Whether in medical procedures, laboratory experiments, or industrial processes, Demax TPU tubes deliver unmatched performance and durability, making them the preferred choice for professionals across various sectors.