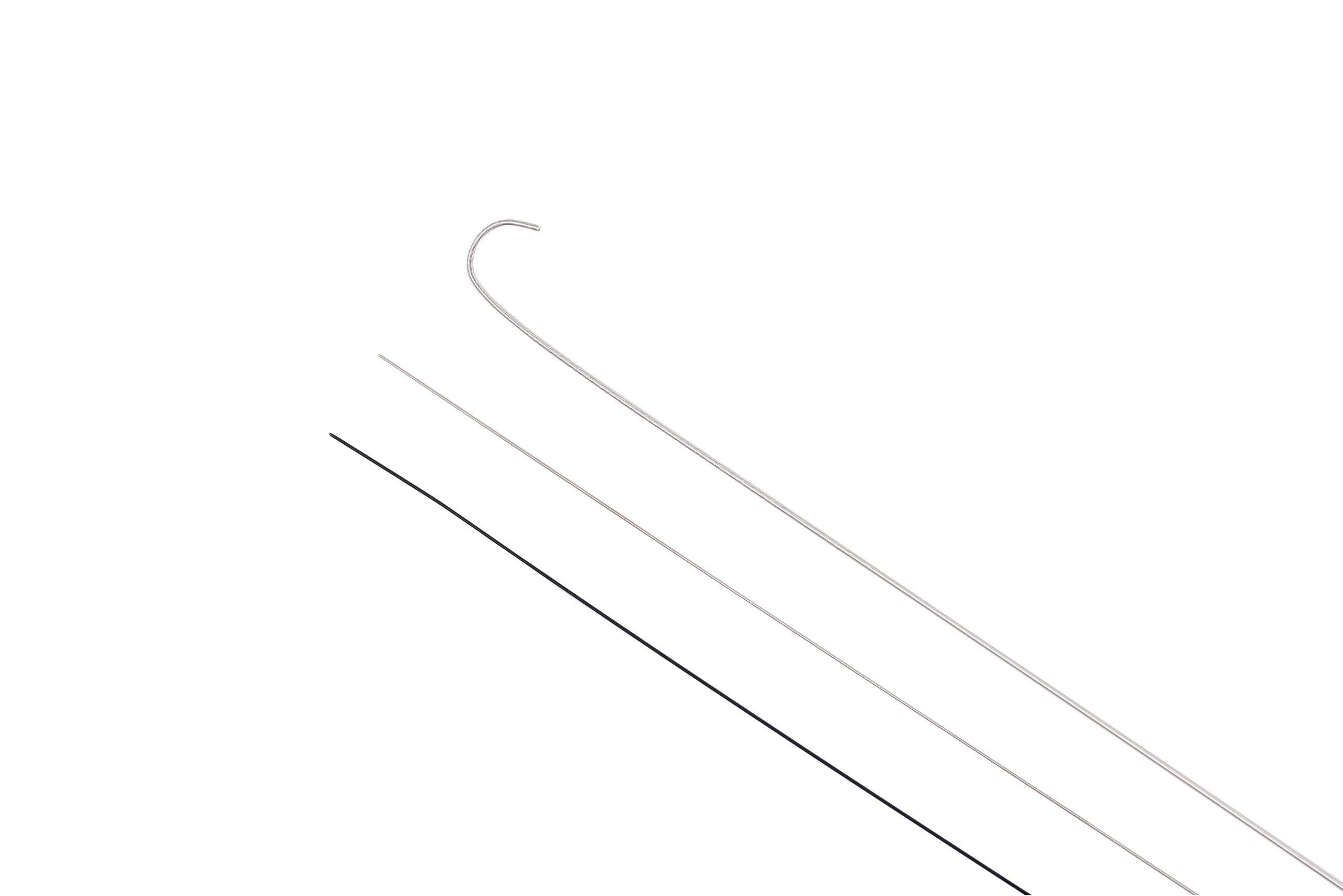

Puncture Guidewire

Puncture Guidewire is composed of a stainless steel core wire and a stainless steel winding wire. The core wire provides stiffness and support for navigating through anatomical pathways, while the winding wire enhances flexibility and maneuverability. This composition ensures the guide wire’s durability and reliability during minimally invasive procedures, allowing healthcare professionals to navigate with precision and achieve successful outcomes for their patients.

- Length: Guidewires are available in various lengths to accommodate different procedural requirements, typically ranging from 450mm to 800mm.

- Diameter: The diameter of guidewires varies depending on the intended application, with options ranging from 0.018 inches to 0.038 inches.

- Flexibility: Guidewires come in different levels of flexibility, allowing healthcare professionals to choose the appropriate stiffness for navigating through different anatomical structures.

- Tip Configuration: Guidewires may feature different tip configurations, such as J-shaped, straight, or angled tips, to facilitate smooth advancement and minimize tissue trauma.

- Radiopacity: Some guidewires are designed with radiopaque markers near the tip to enhance visibility under fluoroscopy or X-ray imaging during placement.

- Vascular Access: In procedures such as central venous catheterization or arterial catheterization, the guide wire helps navigate through blood vessels to access the desired site for diagnostic or therapeutic purposes.

- Biopsy: During image-guided biopsies, the guidewire aids in positioning biopsy needles accurately within target tissues, ensuring precise sampling and diagnosis.

- Drainage Procedures: In interventions such as percutaneous drainage of abscesses or fluid collections, the guide wire assists in navigating through tissues to reach the desired location for drainage catheter placement.

Related products

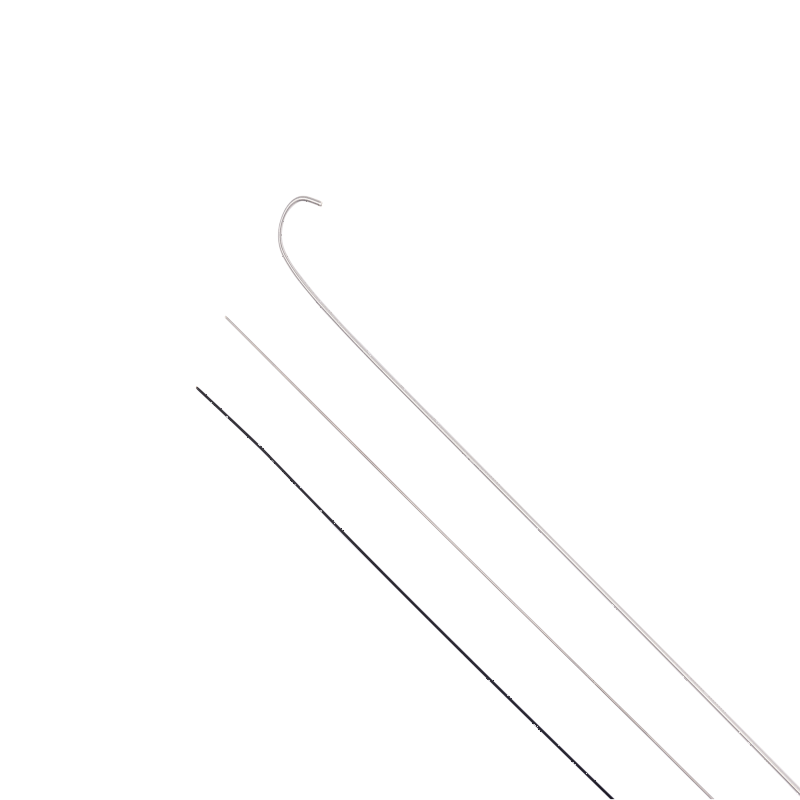

Extra Stiff Guidewire

The Demax Extra Stiff Guidewire is meticulously crafted from high-quality materials to ensure exceptional performance and reliability. Composed of a PTFE-coated stainless steel core wire and a PTFE-coated spring, this guide wire offers optimal strength, flexibility, and maneuverability for navigating through challenging anatomical structures with ease. Additionally, some models feature a radiopaque spring, enhancing visibility under fluoroscopy for precise positioning within the target area. This advanced composition guarantees superior durability, biocompatibility, and performance, making the Demax Extra Stiff Guidewire an indispensable tool for healthcare professionals in various medical procedures.

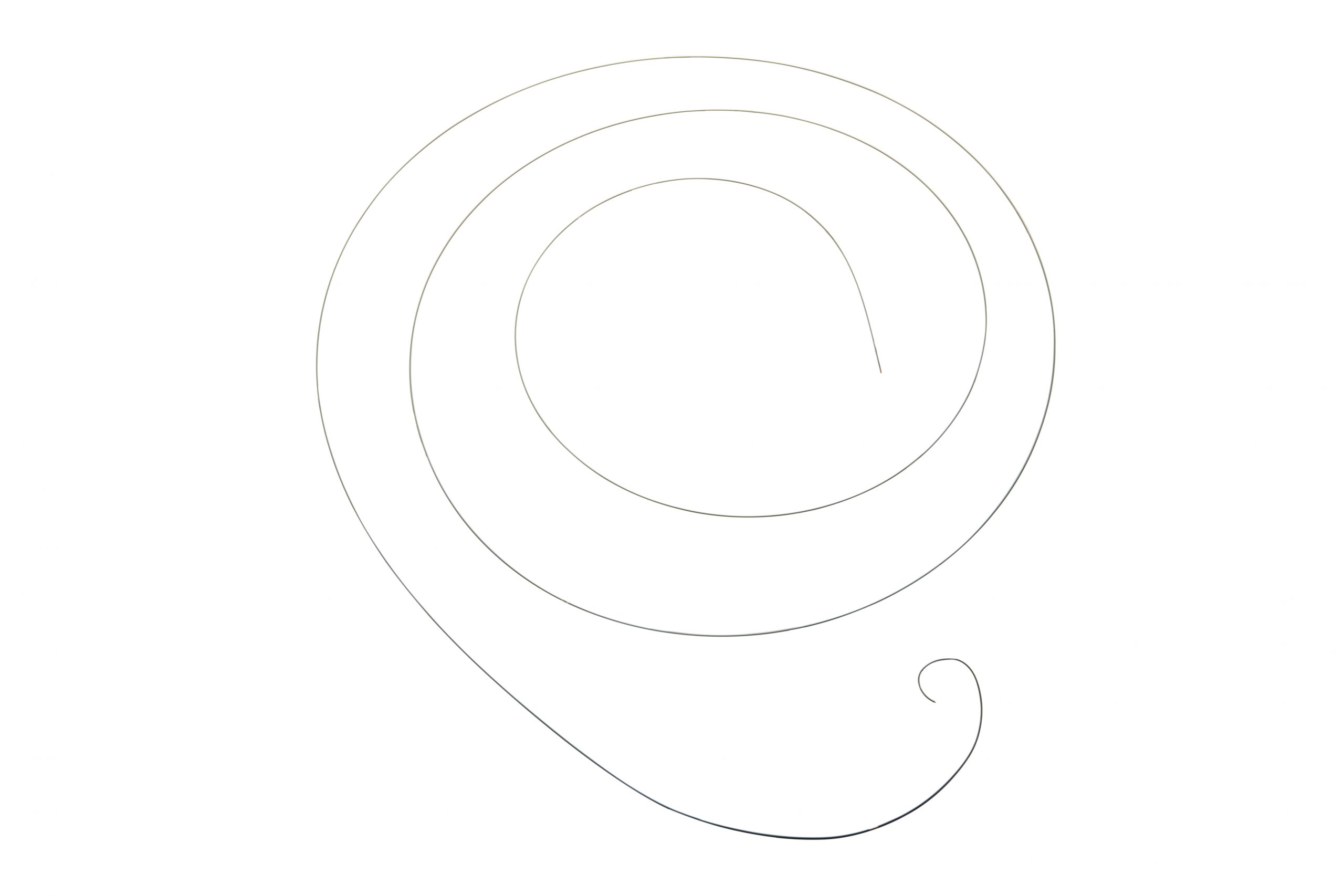

Peripheral Vascular Guidewire

The Demax Peripheral Vascular Guidewire is meticulously crafted using high-quality materials such as stainless steel or tungsten-containing polyurethane tubes, surface coated with hydrophilic coating, known for their exceptional strength, flexibility, and biocompatibility. These materials undergo precision manufacturing processes to achieve the desired diameter, length, and mechanical properties required for effective vascular navigation. The guidewire is coated with a hydrophilic coating to enhance lubricity and reduce friction, ensuring smooth advancement through vascular pathways. With its advanced design and composition, the Demax Peripheral Vascular Guidewire promises to revolutionize peripheral vascular interventions. It offers healthcare professionals a reliable and versatile tool for navigating complex vascular anatomy and delivering optimal patient care.

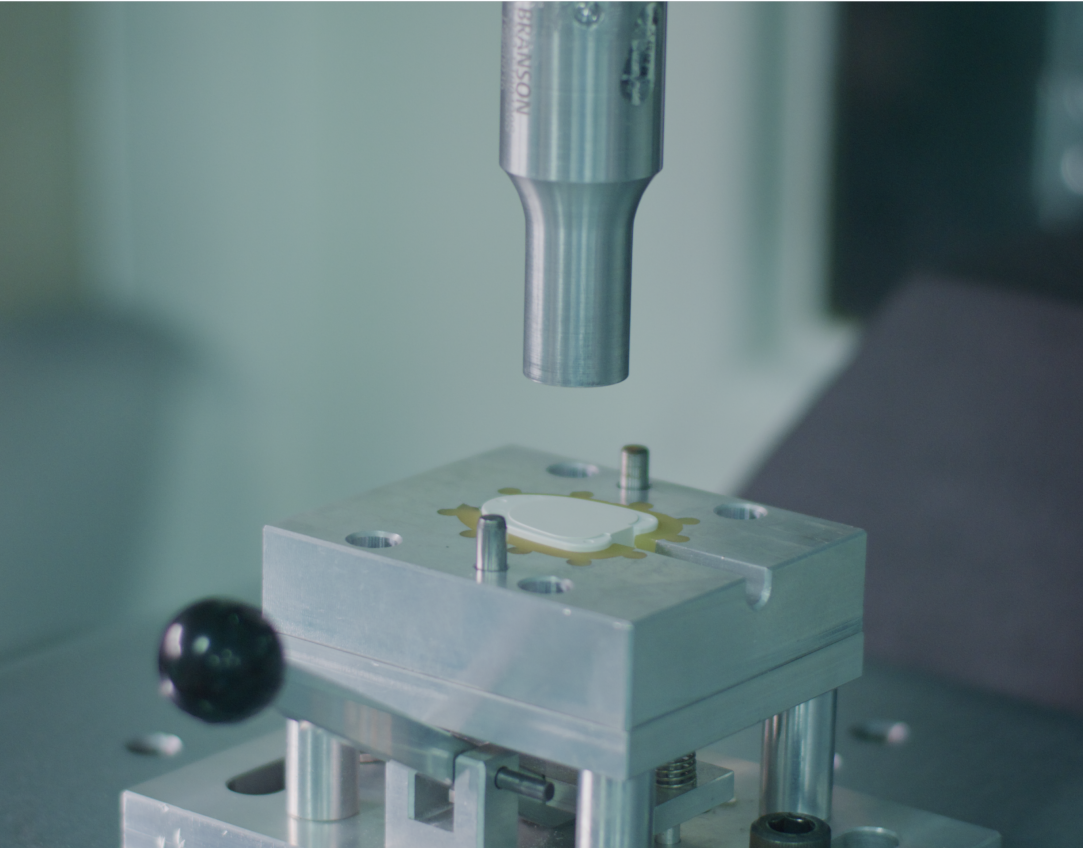

Guidewire Welding

The composition of guidewire assemblies produced by Demax is meticulously crafted to ensure superior performance and reliability. These assemblies typically consist of high-quality materials such as stainless steel, nitinol, or specialty alloys, chosen for their mechanical strength, corrosion resistance, and biocompatibility where applicable, particularly in medical applications. Additionally, advanced welding techniques, including plasma welding, laser welding, and PTCA wire brazing, are employed to securely fuse the components together.