Peripheral Vascular Guidewire

The Demax Peripheral Vascular Guidewire is meticulously crafted using high-quality materials such as stainless steel or tungsten-containing polyurethane tubes, surface coated with hydrophilic coating, known for their exceptional strength, flexibility, and biocompatibility. These materials undergo precision manufacturing processes to achieve the desired diameter, length, and mechanical properties required for effective vascular navigation. The guidewire is coated with a hydrophilic coating to enhance lubricity and reduce friction, ensuring smooth advancement through vascular pathways. With its advanced design and composition, the Demax Peripheral Vascular Guidewire promises to revolutionize peripheral vascular interventions. It offers healthcare professionals a reliable and versatile tool for navigating complex vascular anatomy and delivering optimal patient care.

- Diameter options range from 0.014 inches to 0.038 inches, offering versatility for various procedural requirements.

- Customizable lengths between 40 cm to 300 cm accommodate diverse anatomical variations and procedural needs.

- Crafted from high-quality stainless steel or nitinol alloy for exceptional strength, durability, and flexibility.

- Hydrophilic coating enhances lubricity and reduces friction, ensuring smooth navigation through blood vessels.

- Radiopaque tip provides excellent visibility under fluoroscopy, aiding accurate positioning within the vascular anatomy.

- Optimized flexibility and trackability enable precise control and support during navigation through tortuous vascular pathways.

- Designed to facilitate crossing stenotic lesions, delivering therapeutic devices, and retrieving embolic material.

- Advanced specifications ensure reliable and effective performance in peripheral vascular interventions, enhancing procedural success and patient outcomes.

| Structure | Specification(inch) | Effective Length(cm) | Configuration |

| PTFE-coated core wire surface, DMK-developed hydrophilic coating on the tip, featuring tungsten polyurethane for enhanced imaging | 0.014″、0.018″ | 110cm、182cm、300cm | Angled, Straight |

- Angiography: Assisting in guiding catheter placement for imaging the peripheral vascular system, aiding in the diagnosis of vascular conditions such as arterial blockages or aneurysms.

- Angioplasty: Navigating through narrowed or obstructed blood vessels to facilitate balloon dilation and improve blood flow, essential for treating conditions like peripheral artery disease (PAD).

- Stenting: Guiding the placement of vascular stents to reinforce narrowed arteries, restoring blood flow and preventing re-narrowing (restenosis) after angioplasty.

- Atherectomy: Supporting the delivery and positioning of atherectomy devices to remove plaque buildup from arterial walls, restoring vessel patency and improving circulation.

- Thrombectomy: Assisting in the retrieval of blood clots (thrombi) from peripheral vessels to restore blood flow and prevent complications such as limb ischemia.

- Embolization: Facilitating the precise placement of embolic agents to occlude abnormal blood vessels or control bleeding, often used in the treatment of vascular malformations or tumors.

Related products

Peripheral Micro Guidewire

The peripheral micro guidewire is a specialized medical device used in various diagnostic and interventional procedures to navigate through the peripheral vasculature with precision. Composed of high-quality materials, this guidewire offers exceptional flexibility, durability, and maneuverability, making it an essential tool for healthcare professionals performing peripheral vascular interventions.

Pre-shaped Guidewire

The Pre-shaped Guidewire is a specialized medical device used in various diagnostic and interventional procedures to navigate through anatomical structures with precision. Crafted with precision and using high-quality materials, this guidewire offers exceptional flexibility, durability, and maneuverability, making it an indispensable tool for healthcare professionals performing a wide range of procedures.

Extra Stiff Guidewire

The Demax Extra Stiff Guidewire is meticulously crafted from high-quality materials to ensure exceptional performance and reliability. Composed of a PTFE-coated stainless steel core wire and a PTFE-coated spring, this guide wire offers optimal strength, flexibility, and maneuverability for navigating through challenging anatomical structures with ease. Additionally, some models feature a radiopaque spring, enhancing visibility under fluoroscopy for precise positioning within the target area. This advanced composition guarantees superior durability, biocompatibility, and performance, making the Demax Extra Stiff Guidewire an indispensable tool for healthcare professionals in various medical procedures.

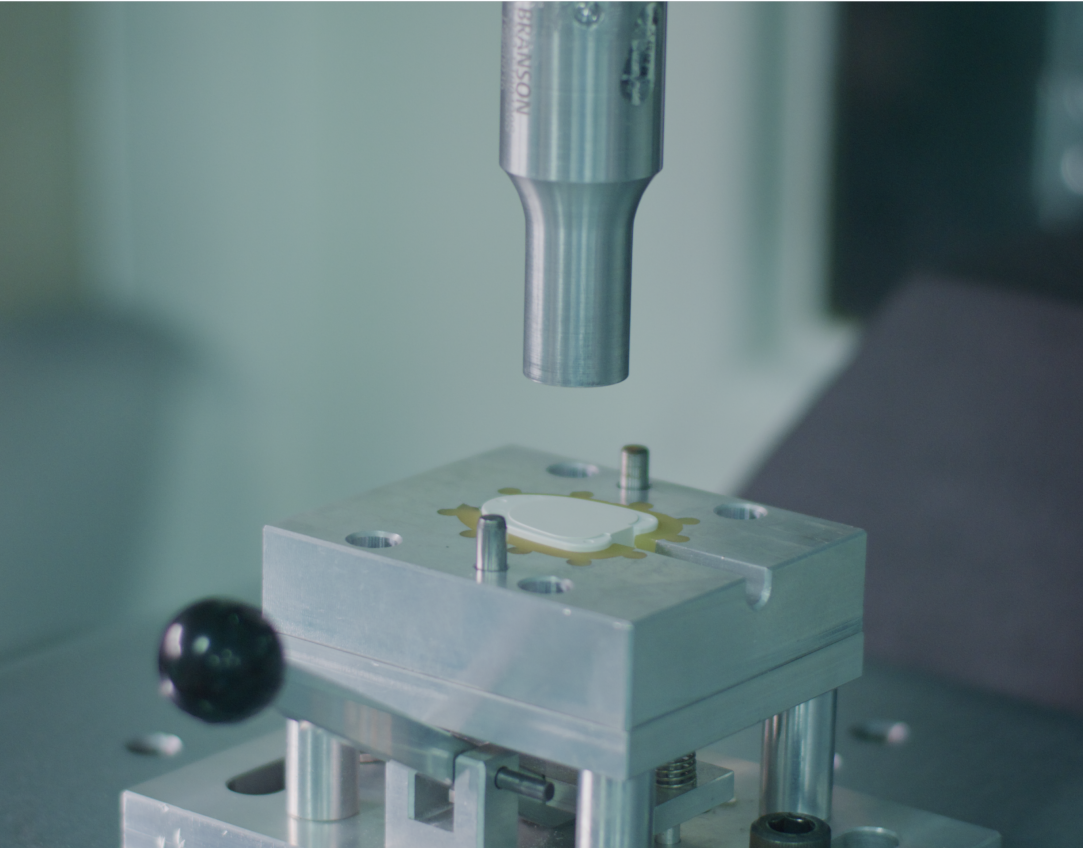

Guidewire Welding

The composition of guidewire assemblies produced by Demax is meticulously crafted to ensure superior performance and reliability. These assemblies typically consist of high-quality materials such as stainless steel, nitinol, or specialty alloys, chosen for their mechanical strength, corrosion resistance, and biocompatibility where applicable, particularly in medical applications. Additionally, advanced welding techniques, including plasma welding, laser welding, and PTCA wire brazing, are employed to securely fuse the components together.