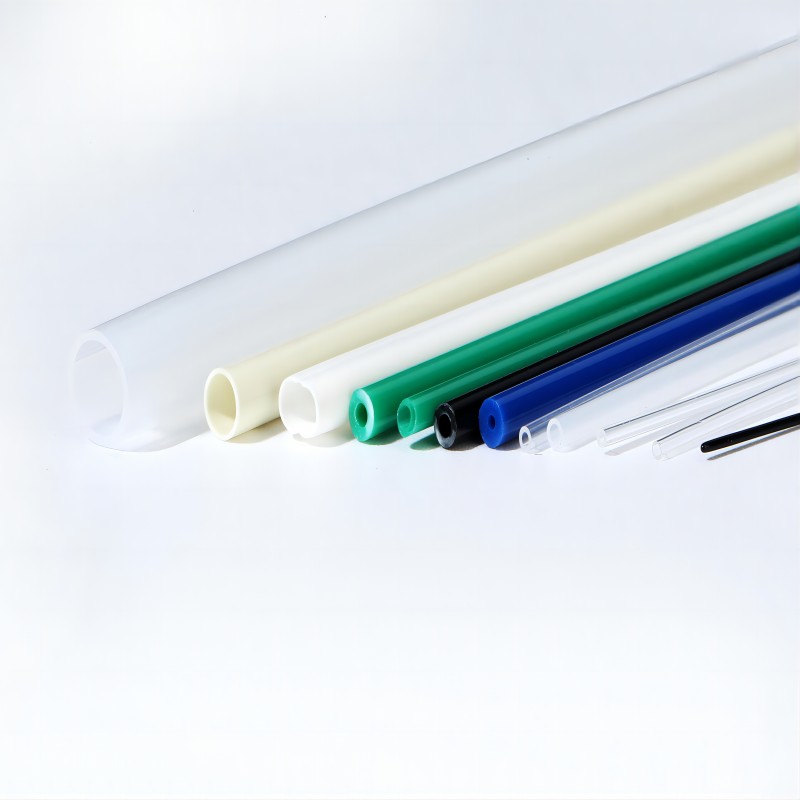

PA Tube

The PA Tube, also referred to as a Single Lumen Tube, is a crucial component utilized in various medical settings for precise fluid delivery or instrument insertion during procedures. It serves as a conduit, ensuring the seamless transfer of fluids or the introduction of medical instruments with accuracy and reliability. Constructed from durable materials, the PA Tube is designed to withstand the rigors of medical procedures while prioritizing patient safety and comfort.

Features

- The composition of Demax’s PA Tube is meticulously crafted to embody durability, flexibility, and biocompatibility, essential qualities for medical tubing applications.

- At its core, the PA Tube is typically constructed from high-quality materials, with polyamide (PA) being a common choice. Polyamide is renowned for its exceptional properties, including robustness, resistance to abrasion, and chemical stability, making it well-suited for medical use.

- The composition of the PA Tube prioritizes biocompatibility, meaning it is inert and non-reactive when in contact with bodily tissues and fluids. This biocompatibility is crucial for ensuring patient safety and minimizing the risk of adverse reactions or complications.

Applications

- PTA balloon single lumen tube

- Angiography catheter

- Guide catheter

- Microcatheter

- Other braided tube inner and outer layers

Technical Parameters

- Outer diameter (mm): 5~10.0

- Outer diameter tolerance (mm): ±02

- Minimum wall thickness (mm): 03

- Wall thickness tolerance (mm): ±02

- Intravenous Therapy: Essential for the precise administration of fluids, medications, and contrast agents in hospital settings, facilitating patient care and treatment.

- Surgical Procedures: Utilized for irrigation, drainage, and instrumentation during surgical interventions, ensuring optimal visualization and control for surgeons.

- Endoscopic Examinations: Integrated into endoscopic devices for visualization and biopsy procedures in gastroenterology and urology, enhancing diagnostic capabilities and patient outcomes.

- Diagnostic Imaging: Employed for contrast media injection and fluid management in medical imaging procedures, contributing to accurate diagnosis and treatment planning.

- Laboratory Research: Applied in laboratory settings for sample collection, analysis, and experimentation, supporting scientific inquiry and discovery.

Related products

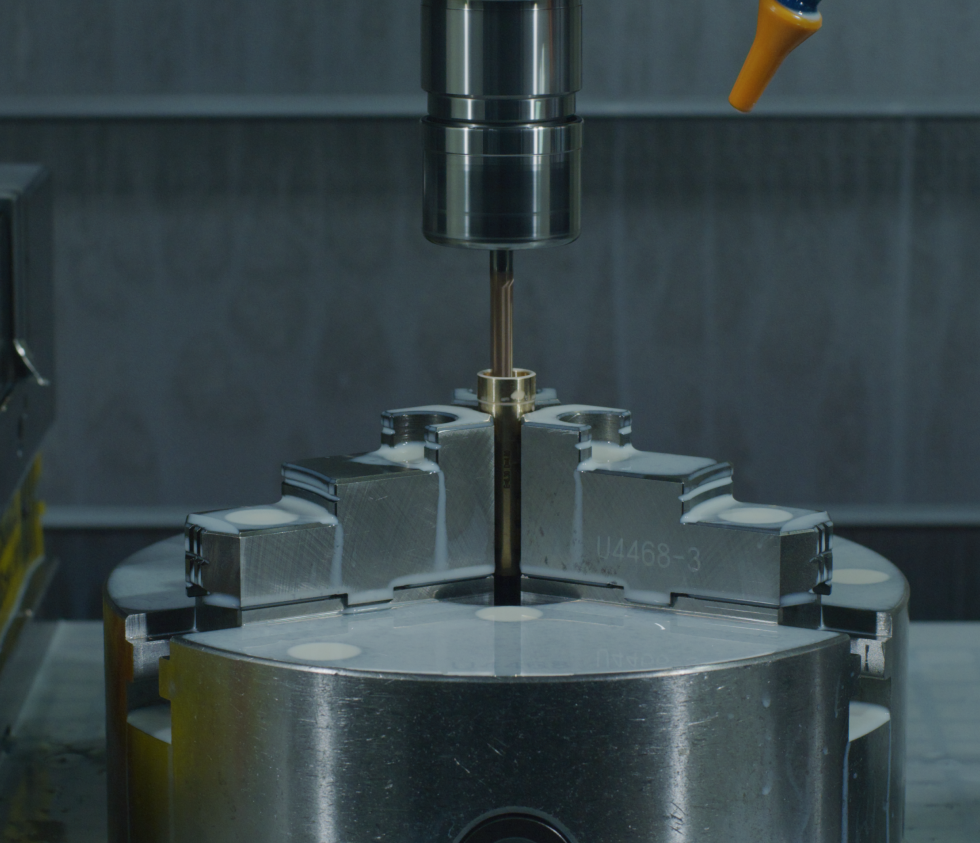

Hook Forming

Demax utilizes high-quality materials such as stainless steel or nitinol for hook forming, chosen for their exceptional mechanical properties, corrosion resistance, and biocompatibility. These materials undergo precise shaping processes to achieve intricate hook configurations tailored to specific medical device applications. With our commitment to quality and precision, Demax ensures that hook-formed components meet the rigorous demands of medical device manufacturing, contributing to the advancement of healthcare worldwide.

PP Tube

The PP Tube is meticulously crafted from high-quality polypropylene, a thermoplastic polymer renowned for its exceptional chemical resistance, durability, and biocompatibility. This composition ensures that the tube is safe for use within the body and can withstand the rigors of medical procedures without compromising patient safety or device performance. Employing state-of-the-art manufacturing techniques, Demax ensures uniformity in dimensions and performance, producing PP Tubes that meet the highest standards of quality and reliability. With Demax’s PP Tubes, healthcare professionals can perform medical procedures with confidence, knowing that they have a dependable and effective tool at their disposal to deliver optimal patient care.

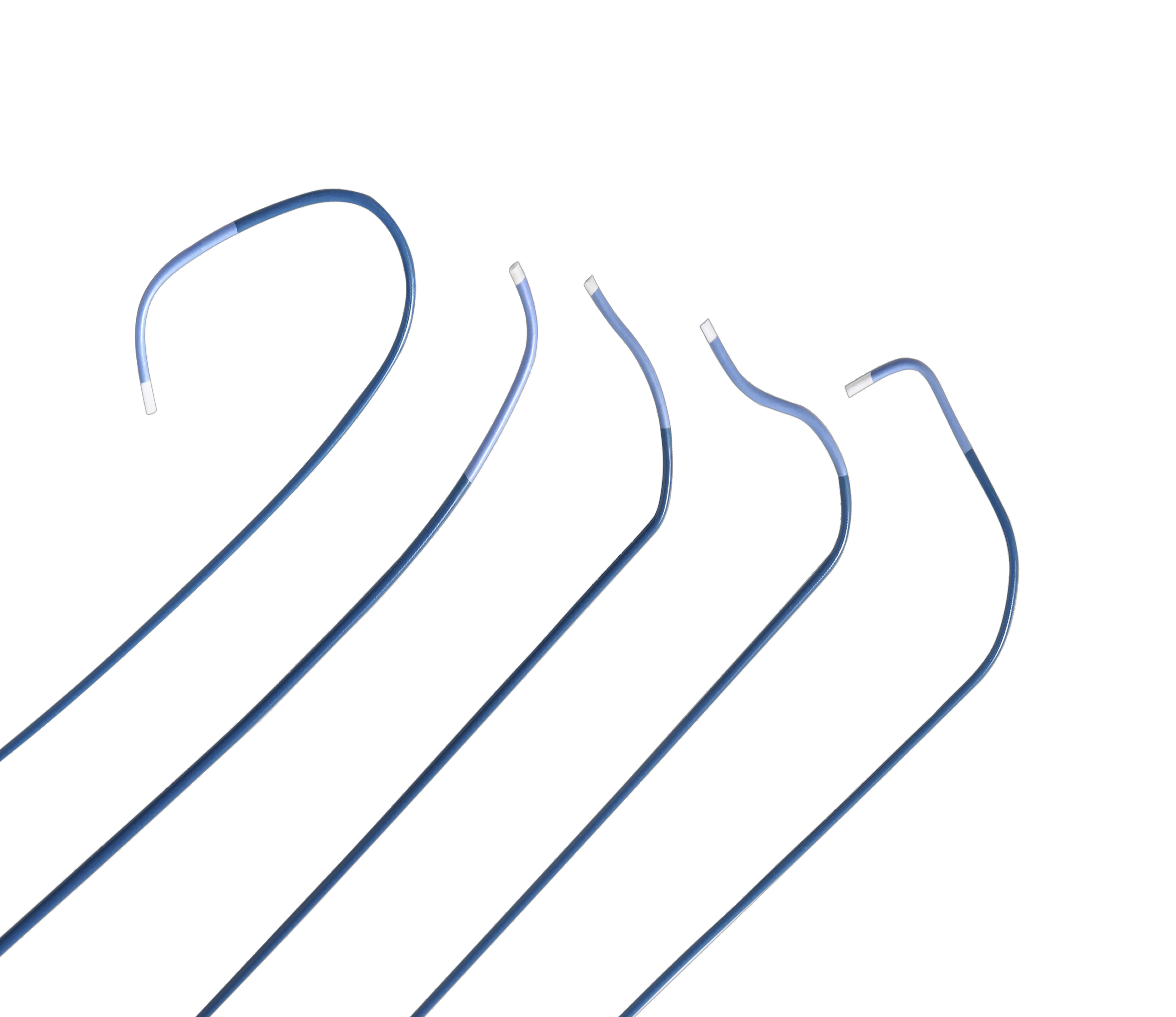

Angiography catheter

Features:

1. The tip is soft to reduce the risk of vascular injury;

2. PEBAX material, stronger configuration shape memory;

3. The port adopts a butterfly-wing ergonomic design, which is convenient to operate and more practical;

4. Good pushability and retractability, easy to control.Guiding Catheter

Guiding catheters are typically composed of biocompatible materials such as polyurethane or nylon, chosen for their flexibility, durability, and compatibility with bodily tissues. The catheter shaft is reinforced with braided or coiled wires to provide structural support and torqueability while maintaining flexibility for navigation through tortuous vascular anatomy. Soft, atraumatic tips minimize trauma to blood vessels during insertion and positioning. Radiopaque markers or bands incorporated into the catheter shaft enhance visibility under fluoroscopy or other imaging modalities, allowing for precise navigation and positioning during procedures. Demax’s guiding catheters are engineered with advanced materials and design features to optimize performance and safety, ensuring successful outcomes in a wide range of interventional procedures.