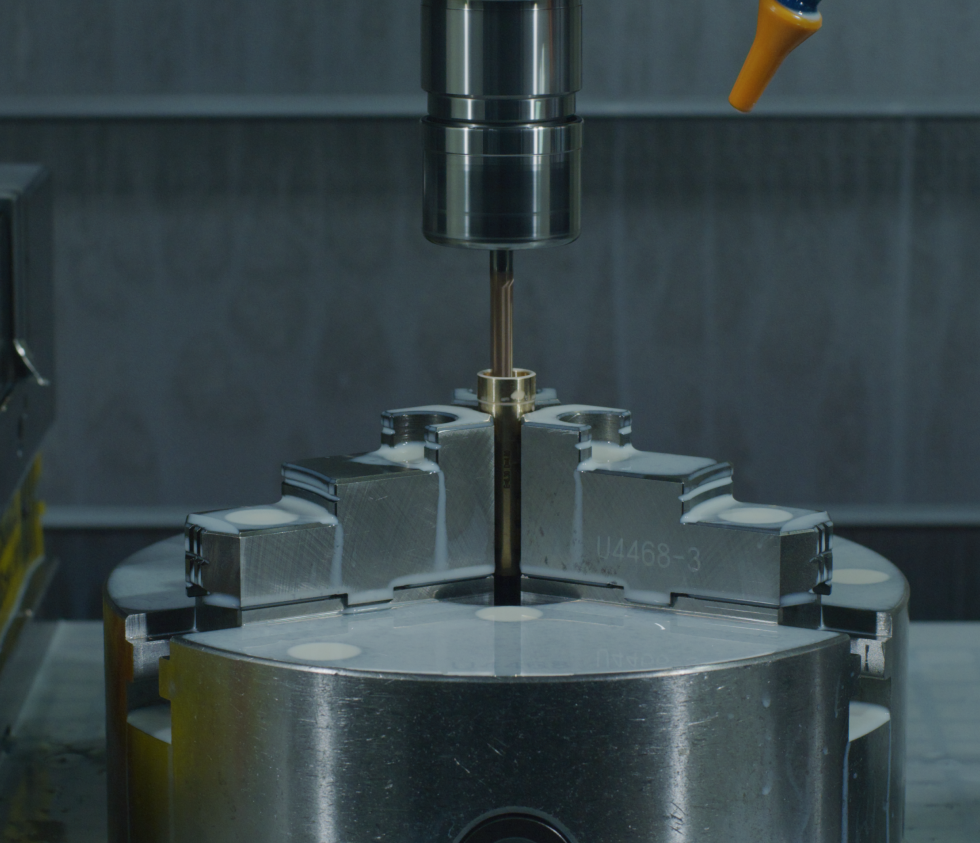

Hook Forming

Demax utilizes high-quality materials such as stainless steel or nitinol for hook forming, chosen for their exceptional mechanical properties, corrosion resistance, and biocompatibility. These materials undergo precise shaping processes to achieve intricate hook configurations tailored to specific medical device applications. With our commitment to quality and precision, Demax ensures that hook-formed components meet the rigorous demands of medical device manufacturing, contributing to the advancement of healthcare worldwide.

- Materials: Demax utilizes high-quality materials such as stainless steel or nitinol for hook forming, ensuring durability, flexibility, and biocompatibility in medical device applications.

- Hook Configurations: Our hook forming capabilities encompass a wide range of configurations, including J-hooks, C-hooks, and complex multi-dimensional shapes, tailored to meet the specific requirements of diverse medical devices and procedures.

- Size Range: Demax offers hook forming services for components ranging in size from micro-scale hooks for minimally invasive procedures to larger hooks for surgical instruments, accommodating a broad spectrum of medical device applications.

- Tolerance: Precision manufacturing processes and stringent quality control measures ensure tight tolerances, guaranteeing consistency and accuracy in hook configurations essential for optimal device performance.

- Guidewires: Formed hooks enable precise navigation and steerability of guidewires during vascular procedures such as angiography and angioplasty.

- Catheters: Hooks incorporated into catheter designs facilitate device placement, manipulation, and anchoring within the body during diagnostic and therapeutic interventions.

- Surgical Instruments: Hook-formed components enhance the functionality of surgical instruments by providing secure grip, precise control, and improved tissue manipulation during surgical procedures.

- Endoscopic Devices: Hooks enable the advancement and positioning of endoscopic devices within the gastrointestinal or respiratory tract, aiding in visualization and treatment of pathological conditions.

- Orthopedic Instruments: Hooks are utilized in orthopedic instruments for soft tissue retraction, tendon manipulation, and bone reduction during orthopedic surgeries.

Related products

PI Tube

The Demax PI Tube is constructed using polyimide (PI), a high-performance polymer known for its excellent mechanical properties and chemical resistance. This tubing is manufactured to meet the stringent standards of the medical industry, ensuring biocompatibility and safety for patient use. It is free from latex, phthalates, and other harmful substances, minimizing the risk of adverse reactions or complications.

Peelable Tube

The Demax Peelable Tube is an innovative medical device designed to provide easy and controlled access to catheters and guidewires during medical procedures. Crafted with precision and utilizing advanced materials, this peelable tube offers exceptional performance and reliability, making it an indispensable tool for medical professionals in various clinical settings.

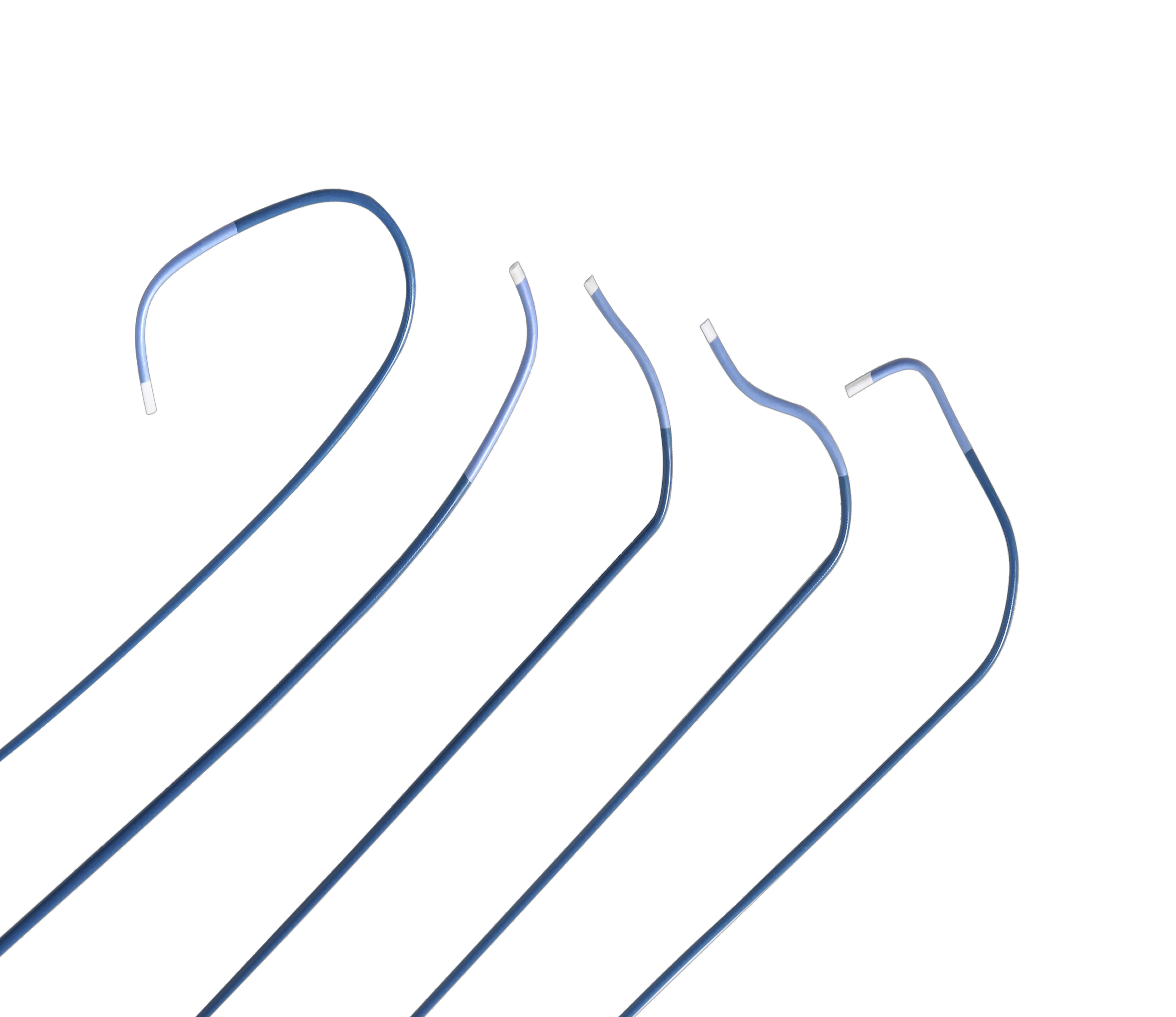

Angiography catheter

Features:

1. The tip is soft to reduce the risk of vascular injury;

2. PEBAX material, stronger configuration shape memory;

3. The port adopts a butterfly-wing ergonomic design, which is convenient to operate and more practical;

4. Good pushability and retractability, easy to control.TPU Tube

Demax TPU tubes are meticulously crafted from Thermoplastic Polyurethane (TPU), a premium synthetic polymer renowned for its exceptional elasticity, durability, and resistance to abrasion, chemicals, and environmental factors. This composition ensures the tubes’ longevity and reliability, even in the most demanding conditions. Demax’s commitment to quality extends to every aspect of their manufacturing process, from sourcing the finest materials to employing advanced production techniques. The result is a TPU tube that meets stringent industry standards, providing customers with confidence and peace of mind in their critical applications. Whether in medical procedures, laboratory experiments, or industrial processes, Demax TPU tubes deliver unmatched performance and durability, making them the preferred choice for professionals across various sectors.