Design

The composition of a coating typically comprises several key components meticulously balanced to achieve desired performance and application properties. At its core lies the binder, responsible for adhesion and film formation on the substrate. Pigments infuse color and other functional characteristics such as UV protection or corrosion resistance, while solvents or carriers facilitate application by dissolving or dispersing the binder and pigments. Additives are incorporated to fine-tune properties like viscosity, anti-foaming, or UV stability, ensuring optimal coating performance. Additionally, fillers enhance properties like hardness and abrasion resistance while serving as cost-effective extenders. Curing agents, in two-component systems, initiate crosslinking reactions with binders, yielding durable, resilient films. Each component’s precise formulation is tailored to specific application requirements, ensuring coatings deliver on durability, aesthetics, and protective capabilities across diverse industries and substrates.

- Modularity and Scalability: Intelligent Manufacturing Production Equipment Design offers modular and scalable solutions tailored to specific production requirements. Modular components can be easily integrated or reconfigured to accommodate changing production demands, offering flexibility and future-proofing capabilities.

- Integration of Sensors and Connectivity: Intelligent Manufacturing Production Equipment Design integrates a wide array of sensors and connectivity solutions to enable real-time monitoring, predictive maintenance, and data-driven decision-making. IoT-enabled devices facilitate seamless communication and collaboration between equipment, optimizing overall system performance.

- AI and Machine Learning Capabilities: Intelligent Manufacturing Production Equipment Design harnesses the power of AI and machine learning algorithms to optimize production processes, anticipate maintenance needs, and optimize resource allocation. These intelligent systems continuously learn and adapt to dynamic production environments, maximizing efficiency and reducing downtime.

- Human-Machine Interaction: Intelligent Manufacturing Production Equipment Design prioritizes human-machine interaction, ensuring user-friendly interfaces and ergonomic design principles. Collaborative robots (cobots) equipped with intuitive control interfaces facilitate safe and efficient collaboration between human operators and automated systems, enhancing overall productivity and job satisfaction.

- Automotive Industry: In the automotive sector, Intelligent Manufacturing Production Equipment Design revolutionizes assembly lines, optimizing processes such as welding, painting, and assembly. Smart robots equipped with AI vision systems precisely manipulate components, ensuring seamless integration and quality control.

- Electronics Manufacturing: Electronics manufacturers benefit from precision-driven processes facilitated by Intelligent Manufacturing Production Equipment Design. Automated surface mount technology (SMT) lines equipped with advanced machine vision systems enable high-speed, high-accuracy placement of electronic components, enhancing production throughput and yield rates.

- Pharmaceutical Production: Pharmaceutical companies leverage Intelligent Manufacturing Production Equipment Design to enhance batch processing, packaging, and labeling operations. Smart conveyor systems equipped with real-time monitoring capabilities ensure compliance with stringent regulatory requirements while improving operational efficiency and traceability.

- Food and Beverage Industry: In the food and beverage sector, Intelligent Manufacturing Production Equipment Design optimizes packaging, filling, and labeling processes. Intelligent packaging machines equipped with sensors and IoT connectivity detect anomalies in packaging integrity, reducing waste and enhancing product safety.

Related products

Coating

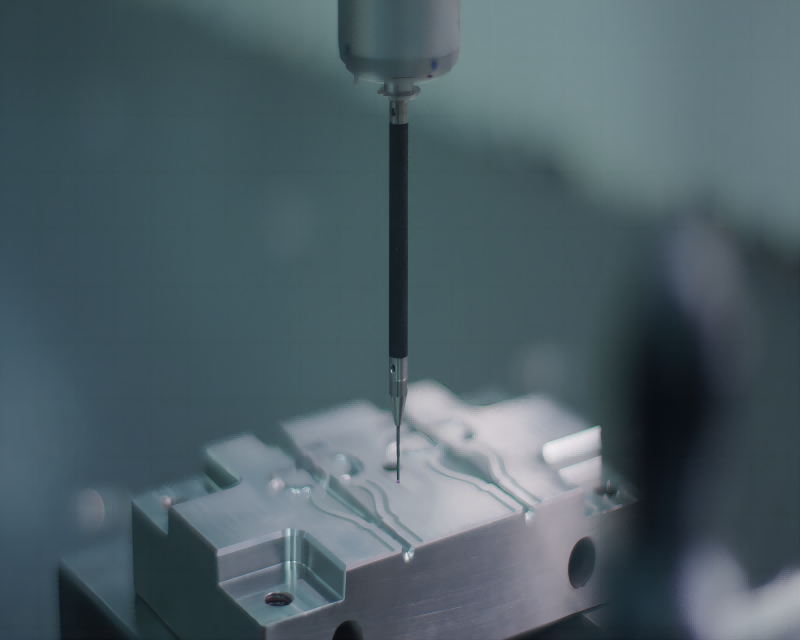

Intelligent Manufacturing Production Equipment Coating comprises a sophisticated blend of materials meticulously formulated to provide exceptional protection and durability to industrial machinery. At its core are polymer resins, engineered to imbue the coating with robustness, resilience, and adhesive properties. These resins form the backbone of the coating, ensuring it adheres firmly to the surface of the machinery, resisting peeling, chipping, or delamination over time.

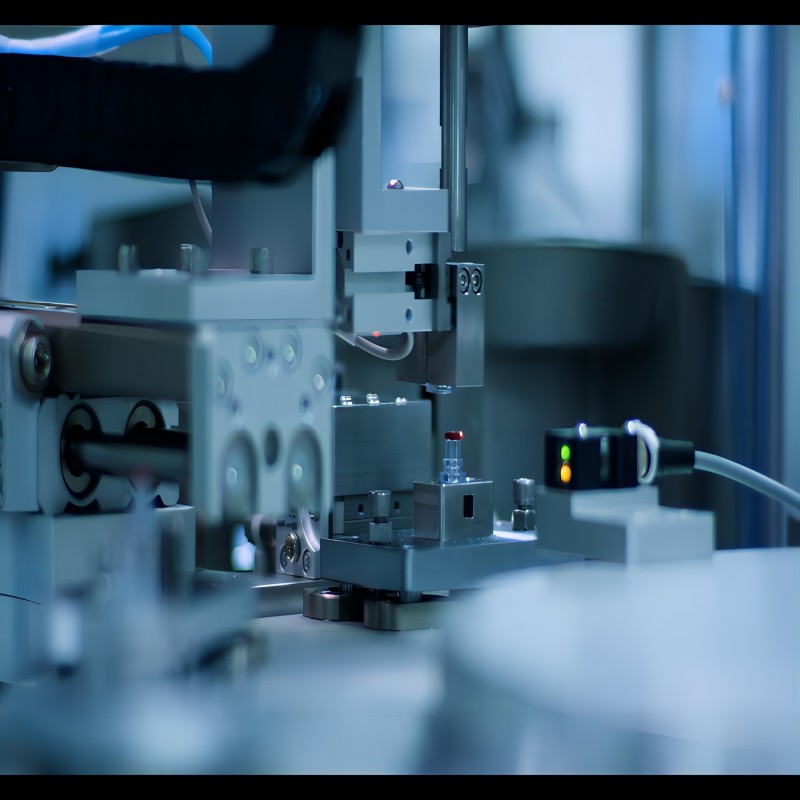

Testing

Demax’s Intelligent Manufacturing Production Equipment Testing service combines advanced testing methodologies, state-of-the-art equipment, and experienced professionals to ensure the reliability and performance of automated manufacturing systems. The composition of this service includes a variety of testing protocols tailored to specific requirements, advanced testing equipment such as specialized rigs and data acquisition systems, and a team of skilled testing engineers with expertise in industrial automation and quality assurance.

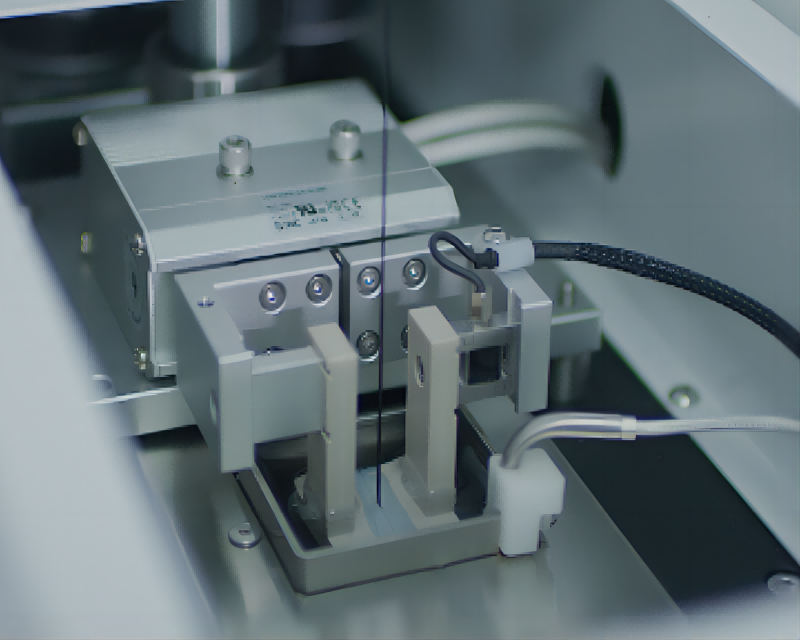

Assembly

The assembly of Intelligent Manufacturing Production Equipment at Demax is a meticulously coordinated process that ensures precision, efficiency, and reliability. It begins with the fabrication of individual components, including robotic arms, conveyor systems, CNC machines, 3D printers, smart sensors, and IoT devices, each manufactured to the highest standards of quality and precision. Once the components are ready, our skilled technicians meticulously assemble them according to the detailed design specifications. Every step of the assembly process is carefully monitored to ensure proper alignment, integration, and functionality of each component.